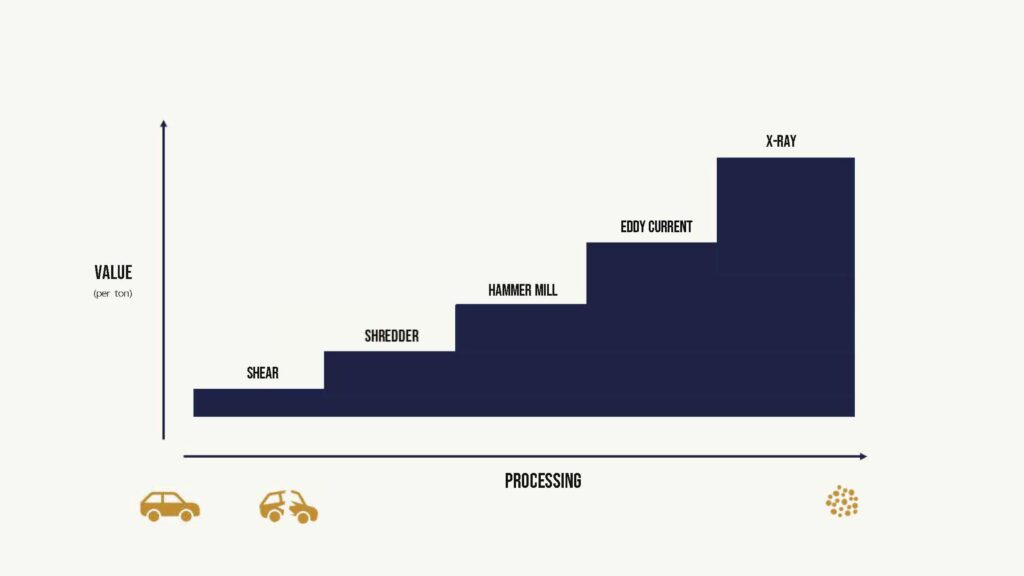

From the raw and unprocessed start to the most precious and purest fractions, we dive into how technological innovation has transformed the scrap industry into a treasure trove of resources and sustainable value creation.

Step 1: Primary Scrap – From Chaos to Potential

Our journey begins with primary scrap – the unprocessed raw material. Primary scrap represents scrap in its most basic form, where the value is modest and the size of the scrap is largest. Many know that there is hidden potential in primary scrap, but may not have the time or resources to explore it.

Often the first experience on the scrap journey will be the inside of scrap shears, which process and cut the materials into more manageable sizes. Once the material has been through the shears, it becomes smaller, making it easier and cheaper to transport, and it reaches a size that smelters can use. This already adds value to the scrap.

At this stage, we recommend scrap shears from LEFORT and COPEX that can produce from 15 tons per hour to 130 tons per hour. You can choose between mobile or stationary scrap shears and balers.

You can read more about these scrap shears here: LEFORT | COPEX

Step 2: Shredders – Value grows through Shredding

After the scrap has undergone its first transformation in the scrap shears, the shredder is ready to take over. These machines break down the primary scrap further. It is much cheaper and less resource-intensive for smelters and larger sorting units to handle the scrap after it has been shredded. The size of the scrap metal becomes more homogeneous and it starts to take shape to be sorted in the next steps. This process therefore makes your scrap even more desirable on the market.

Shredders can be a mouthful to get to grips with, and we are of course happy to help you with that. We primarily advise on shredders from FORREC and PRALL-TEC, who have specialized in this field for many years.

You can read more about these shredders here: FORREC | PRALL-TEC

Step 3: Hammer Mill – The keyword is Homogeneity

To understand how your scrap material can be sold at a higher price, it makes sense to look at the challenges that sorting facilities and smelters face when working with the materials – as this could very well be where your scrap ends up.

The facilities responsible for sorting the fractions have invested a lot of money in technology that can handle different types of metals. But in order for them to fully utilize these technologies, it is necessary to have homogeneous fractions that have a sortable size for the machines at the plant. Therefore, it doesn’t matter if the fractions you deliver are 10 or 500 mm. Typical fractions are between 10 – 200 mm.

For smelters, large amounts of energy are required to heat the metal fractions in the furnaces. The larger the scrap fractions, the more energy is needed per kg of metal. And we’re not talking small quantities here. So there are two factors that are highly prioritized by the smelters. 1. The metal fractions should be as small as possible, as they require less energy to handle, and 2. The metal fractions should be as homogeneous as possible, because it is important to be able to count on the fractions that enter the furnace.

This means that as long as the scrap still has irregular sizes and shapes, it will complicate the further process in sorting plants and smelters. This is why homogeneous sizes and shapes are in high demand in the market. So why not meet their needs and reap the benefits of the added value you can demand for your metals?

To meet the demand for homogeneity, we will in many cases recommend using a Hammer Mill. A Hammer Mill further refines the material and makes the fractions ready to be sorted. This treatment process makes it easier to separate different materials and makes you a more attractive supplier in the market.

Read more about Hammer Mills here: Hammer Mills

Step 4: Separation of Iron & Metals – The Overlooked Gold

In step 4, a paradigm shift occurs. From focusing on processing and compartmentalization, the focus will shift to sorting. There are huge financial rewards for those who reach this step of the ladder. Because this is where the hidden “gold” of scrap material is found.

The prize goes to those who are able to produce pure metal fractions. For example, pure copper or aluminum. If you manage to extract these pure metal fractions, they can be used directly in the production of new copper and aluminum products on the market. It goes without saying that these fractions are extremely valuable in a world where there is a scarcity of resources combined with a strong interest in the circular economy.

There are various technologies available to achieve pure metal fractions. Often the process begins by ensuring that ferrous materials are removed from the non-ferrous ones – a magnetic drum, overband magnet or eddy current magnet can be used. Depending on the application, these technologies will ensure you have clean non-ferrous metals for further sorting.

Read more about the technologies here: STEINERT

Step 5: Fine Sorting – Scrap Value Peak

Once we’ve ensured that no ferrous materials enter the process, you may be left with a mixed bag of non-ferrous metals (aluminum, brass, copper, lead, tin, nickel, silver, gold, etc.) To separate this cocktail of metals, you need high-tech machines based on X-ray and sensor technology. The result is the finest and cleanest fractions available on the market.

This is the critical moment when the materials reach their highest value, as the metals are coveted resources in the recycling world. This is where we find the most precious resources in the scrap pile.

Our goal is to help companies across Scandinavia optimize this process to get the highest yield from their materials. We draw on years of experience and expertise in scrap processing to ensure that nothing goes to waste and that our customers maximize the value of their resources.

Scrap processing is not only a financial gain, it is also a valuable contributor to a more sustainable future. By reducing waste and maximizing value, we reduce our environmental impact and move towards a more sustainable future.

Dive into our universe of exciting machines and technologies for the recycling industry at www.vb-sortering.dk!

Or contact us immediately on tel. +45 43 96 41 22