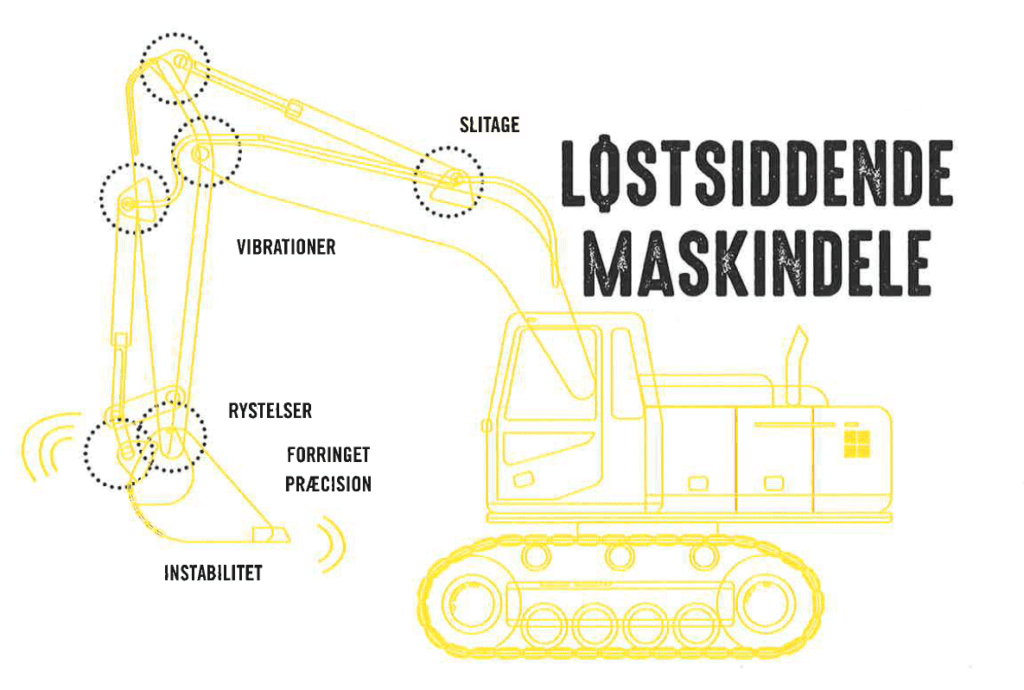

All machines wear out over time. The “ears” become more and more oval, the joints become more and more loose and the machine becomes more and more annoying.

You probably know the feeling. You’re driving around in a new excavator. The excavator works perfectly. After a while, the excavator arm becomes less precise in its movements. Before long, you’re left with an excavator arm that feels both loose and imprecise. Blurring has occurred in the digging arm.

Expander – A simple and permanent solution

All machines wear out over time. The “ears” become more and more oval, the joints become more and more loose and the machine becomes more and more annoying.

You probably know the feeling. You’re driving around in a new excavator. The excavator works perfectly. After a while, the excavator arm becomes less precise in its movements. Before long, you’re left with an excavator arm that feels both loose and imprecise. Blurring has occurred in the digging arm.

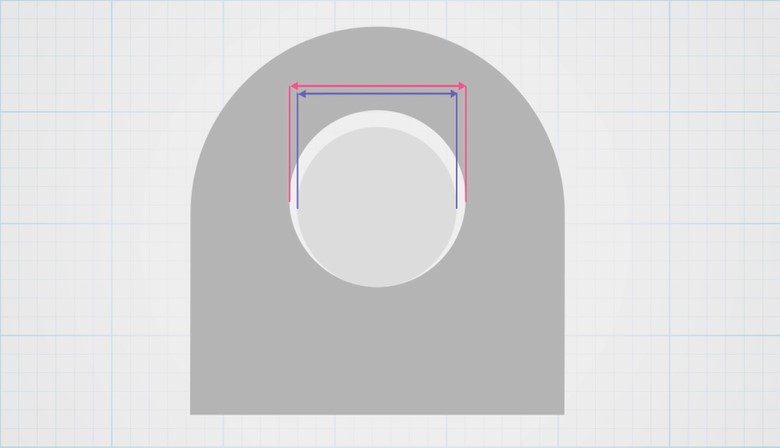

The problem with a regular pin bolt is that it will always be a millimeter or two smaller than the hole – otherwise the bolt simply cannot be inserted. Those few millimeters allow for wear and tear over time. The expander bolt solves that.

Expander – A profitable solution

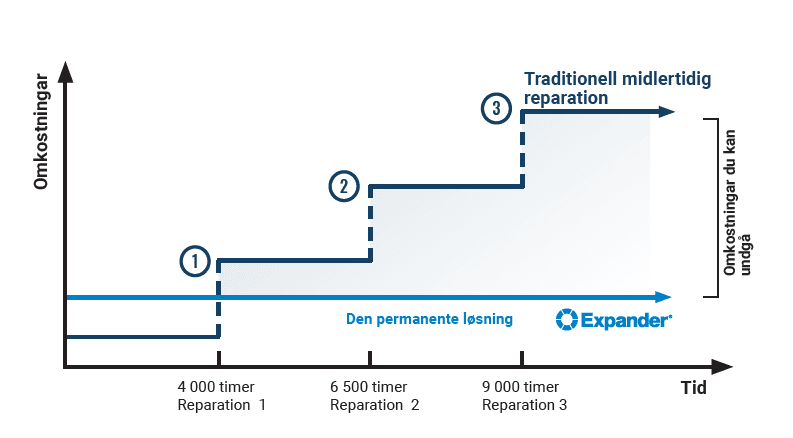

It’s very simple. It’s not the pin bolt that’s expensive, it’s the repairs.

The Expander System is a permanent solution from the day the bolt is installed. Expander provides a 10-year functional warranty or the equivalent of 10,000 hours.

Adding an expander bolt to your machine not only eliminates looseness in the excavator arm, it also eliminates the need for workshop visits due to wear and tear in the loose joints.

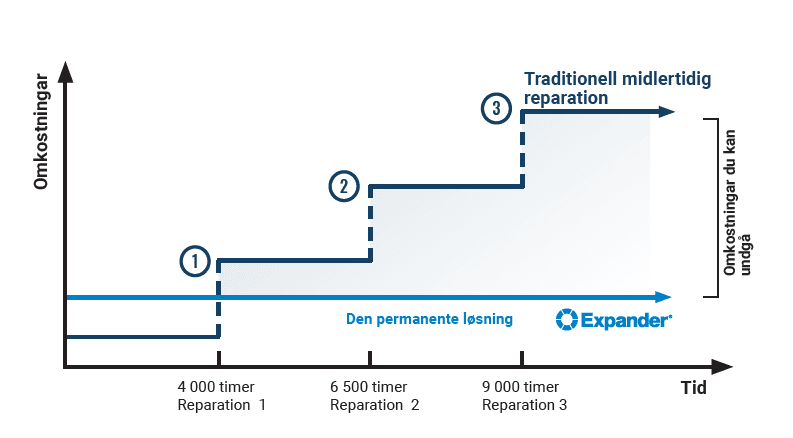

As illustrated in the picture, this means that you can achieve profitability already after the first repair. As an additional side benefit, you add value to the machine until the day it is sold.

A profitable solution

It’s very simple. It’s not the pin bolt that’s expensive, it’s the repairs.

The Expander System is a permanent solution from the day the bolt is installed. Expander provides a 10-year functional warranty or the equivalent of 10,000 hours.

Adding an expander bolt to your machine not only eliminates looseness in the excavator arm, it also eliminates the need for workshop visits due to wear and tear in the loose joints.

As illustrated in the image, this means that you can achieve profitability already after the first repair.

As an extra side benefit, you add value to the machine until the day it’s sold.

The Expander System – In short

Expander System

The Expander System eliminates this size difference by using special sleeves that expand in the hole. When installed correctly, the expander bolt adapts 100% to the hole and permanently removes all slippage.

You can read more about the Expander System here.

Login to expander.dk and find the expander bolt for your machine

Press the “Find machine” button to find your machine in the database and the position on the machine that needs a new pin bolt. Then log in to expander.dk to order the expander pin. Don’t have a login for expander? Contact us and we will look at it together and find a price and delivery for you.

Find the expander bolt for your machine

Press the “Find machine” button to find your machine in the database and the position on the machine that needs a new pin bolt.

Then log in to expander.dk to order the expander bolt. Don’t have a login for expander? Contact us and we’ll take a look at it together and find a price and delivery for you.

If in doubt, contact us and we’ll help you right away.

Contact us

Jan Pedersen

Authorized Expander importer

Email: vb@viggobendz.dk

Tel: +45 43 96 41 22

Mob: +45 24 85 52 85