Fire

Westeria

Westeria is known for their innovative solutions that accurately and efficiently separate materials such as plastic, metal and wood using their air separation systems. Westeria has its own test centers where their technology is continuously tested and optimized to ensure high reliability and optimal performance. Their systems are designed to be energy efficient and durable.

At Viggo Bendz, we have gathered a number of the best suppliers on the market, including Westeria, who are experts in their field.

We sell both standalone machines and complete solutions, with each supplier contributing their specialized technology. By combining Westeria’s systems with components from other leading manufacturers, we can offer complete solutions optimized for each customer’s specific recycling and material handling needs.

AirStar®

AirStar® evolution is Westeria’s latest generation of wind turbine technology, setting new standards for efficiency, precision and ease of use. With decades of experience in air separation, the machine has been optimized to improve availability, maintenance and operational performance.

AirStar® evolution is suitable for a wide range of materials, including:

- Household waste

- Plastic

- Waste wood

- Minerals

- Mixed construction waste

- Glass waste

- Industrial waste

- Scrap metal

Key features and technical data

-

NotusAir system – The innovative air separation system ensures precise air control and optimal separation. The system is developed with customized components to achieve maximum efficiency in the sorting process.

-

Adjustable fan with frequency control – AirStar® evolution is equipped with an adjustable fan that reduces energy consumption by over 30% compared to traditional air dampers while minimizing noise pollution.

-

Extra wide air nozzle – The larger nozzle opening enables a more uniform and powerful airflow, significantly improving separation.

-

Optimized air management system – A carefully tuned airflow ensures efficient transport of the light material to the light fraction chamber. A specially designed extraction hood also enables safe recirculation of the air.

-

Automatic parameter control – The separation process can be precisely adjusted without the use of tools. Adjustment options include a horizontally moving separator drum, adjustable feed belt height, variable nozzle angle and pressure control.

AirStar® evolution is constructed with a user-friendly design that provides easy access from all sides for maintenance and inspection. Large glass sections make it possible to monitor the separation directly, simplifying both operation and service.

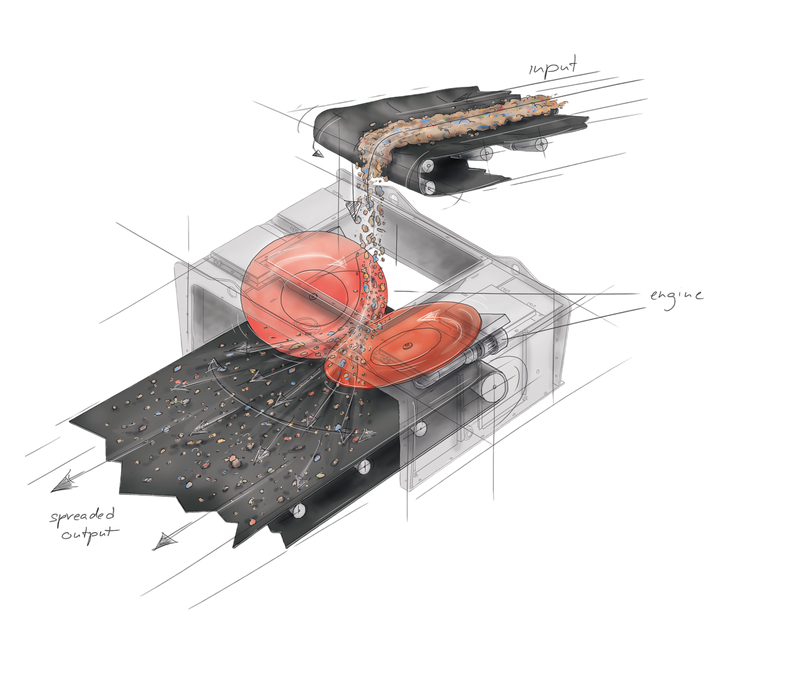

How does the technology work?

The system is based on an acceleration belt, an air stream, and a rotary separation cylinder. The materials are spread in a uniform layer on the belt and accelerated to a certain speed, after which they meet an air stream that separates the light and heavy materials by their weight and shape.

The compact and robust design makes AirStar® evolution one of the most efficient wind technologies on the market, with a capacity of up to 400 m³/h.

Airlift®

Westeria’s AirLift® is a high-tech air separator designed for precise separation of materials with very similar specific weights. This technology is particularly effective at removing light impurities from material streams, ensuring a high degree of purity in the sorted materials.

Key features:

-

High efficiency: AirLift® achieves a higher efficiency compared to traditional overbelt vacuum systems, resulting in a cleanliness rate of over 99%.

-

Precise adjustment: Ability to accurately set ballistic trajectory, air speed and visibility, ensuring optimal separation.

-

High capacity: Can handle material flows with a maximum flow rate of 320 m³/h.

Key features and technical data

-

Plastic recycling: Efficient removal of light impurities like PE film or paper labels from valuable PET fractions.

-

Biological waste: Excellent for freeing biological waste from plastic contaminants, improving compost quality.

Components of the AirLift® system:

-

AirLift®: The central unit is a vacuum chamber that efficiently extracts ultra-light impurities from material streams.

-

AirWheel®: A rotating screening drum that separates the removed materials from the airflow.

-

SpeedCon®: A high-speed buckling conveyor belt that transports material at speeds up to 4 m/s, improving separation efficiency.

AirLift®’s advanced technology and precise adjustability make it an indispensable component in modern sorting plants where high cleanliness and efficiency are essential.

DiscSpreader®

Westeria’s DiscSpreader® is a patented solution designed for optimal material distribution in various sorting processes. This compact unit can be easily mounted on any type of conveyor and requires minimal maintenance.

-

Low maintenance requirements: The short contact between material and machine minimizes cleaning work. The solid disks are durable even in demanding conditions and are easy to replace. The motors are fully protected from material and easily accessible.

-

Quick and easy installation: Thanks to its standardized design and pre-assembled units, DiscSpreader® is quickly ready for shipping and can be assembled locally without specialist knowledge.

-

Flexible material feeding: With different feed funnels, material can be fed from all sides, allowing complete freedom in system design.

Key features and technical data

-

360° material feeding: Enables flexible material feeding from all sides, allowing freedom in plant design.

-

Space-saving design: DiscSpreader® is up to 7 meters shorter than traditional distribution systems such as vibrating tables, reducing space requirements in the facility.

-

Precise alignment of distribution discs: Ensures even and efficient material distribution across the entire width of the conveyor belt, which is essential for subsequent sorting processes such as NIR, ballistic sorting or air separation.

Technical details:

-

Standard distribution widths: 1500 mm, 2000 mm, 2500 mm, 3000 mm and 3500 mm.

-

Transport: The entire unit fits in a standard 20-foot sea container.

-

Compatibility: DiscSpreader® is compatible with all commercially available sorting machines, including NIR, air classification and ballistic sorting machines.

If you need an efficient solution for precise and even material distribution in your sorting plant, Westeria DiscSpreader® is an obvious choice. With its compact design, low maintenance requirements and flexible customization options, it ensures optimal material distribution, improving sorting quality and overall process efficiency.

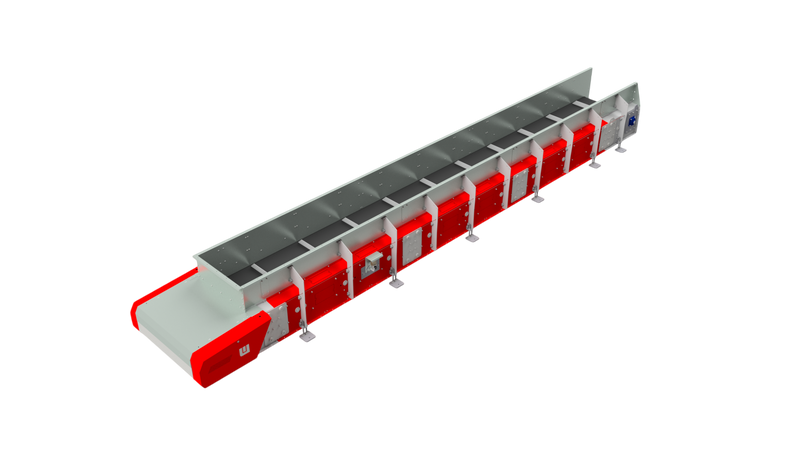

MovingFloor®

Westeria’s MovingFloor® is a flexible and modular bunker system designed for precise dosing and continuous material feeding. This system is ideal for handling a wide range of materials including alternative fuels, compost and mixed construction waste, ensuring a smooth and reliable flow throughout the process.

Key features and technical data

-

Modular design: MovingFloor® can be easily expanded or adapted in size, providing long-term value and operational flexibility.

-

Quick assembly: Thanks to the modular principle, the system can be assembled quickly and easily, significantly reducing installation time.

-

Minimal maintenance: By eliminating components such as bearings, shafts, chains and conveyors, wear and maintenance costs are minimized.

-

Hydraulic pistons: The system can be configured with five different hydraulic cylinder pistons in different diameters to meet specific applications, classified as light (up to 0.3 t/m³), medium (up to 0.6 t/m³) and heavy (up to 1.2 t/m³).

-

Integrated leveling roller: To ensure a constant material supply even when the hopper is fully loaded, an equalizing roller can be installed. This prevents material jams between the housing wall and the drum and the height of the rollers can be easily adjusted.

Technical specifications:

-

Volume: Available capacities range from 50 m³ to 315 m³.

-

Inner length of the bunker: Varies from 5,540 mm to 29,300 mm, depending on the model selected.

MovingFloor®’s versatility and efficient design make it an ideal solution for companies looking for reliable and customizable material handling systems.

Conveyor belts (WeKea)

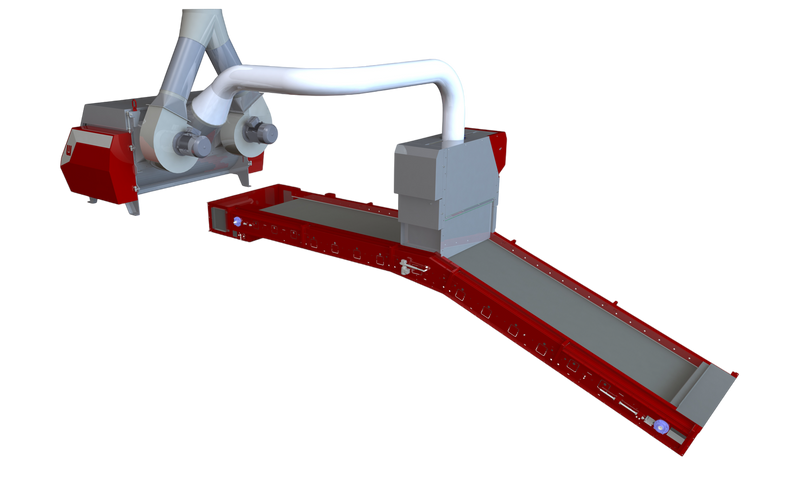

Westeria’s WeKea® system revolutionizes conveyor belt technology by offering modular and flexible solutions that can be adapted to different industrial needs. After five years of development and optimization, Westeria introduces four types of WeKea® conveyor belts: FlatCon, UCon, SteelCon and ChainCon.

Key features and technical data

-

Online configurator: Customers can quickly and easily design their desired conveyor belt using an online configurator, resulting in an official quote within minutes.

-

Modular design: The conveyor belts are designed with standardized components, enabling fast production and delivery. This modular system also allows local staff to assemble the conveyors without the need for specialized knowledge.

-

Space-saving transportation: The compact components significantly reduce transportation costs as they require less cargo space compared to traditional systems.

The four WeKea® conveyor belt types:

-

FlatCon: A versatile and flexible conveyor belt that can be used in various applications.

-

UCon: Designed to handle all types of bulk materials efficiently.

-

SteelCon: An extremely robust conveyor belt, ideal for the most demanding applications.

-

ChainCon: The best chain conveyor on the market, known for its durability and reliability.

The WeKea® system offers an efficient and economical solution for companies looking for reliable and customized conveyor belt solutions.