Fire

Trevi Benne

Trevi Benne is known for their high-quality hydraulic equipment for demolition and recycling. With over 30 years of experience and a strong focus on innovation, they deliver solutions that combine precision, durability and efficiency, making them a global player in their field.

Trevi Benne’s products are Italian quality products, known for their robust construction and ability to handle the most demanding demolition and recycling tasks. Their machines, such as the CS series of hydraulic shears, are built to cut through metal and steel structures with ease, while proving to outlast competitors’ products due to their durable design.

The FR Series pulverizers and crushers effectively break down concrete and separate metals from building materials, making them ideal for tough work in difficult conditions.

With a combination of advanced hydraulic technology and outstanding durability, Trevi Benne products ensure not only fast and precise demolition, but also long life in demanding environments. At Viggo Bendz, we offer Trevi Benne’s products as part of our range, bringing high performance and reliability to any project.

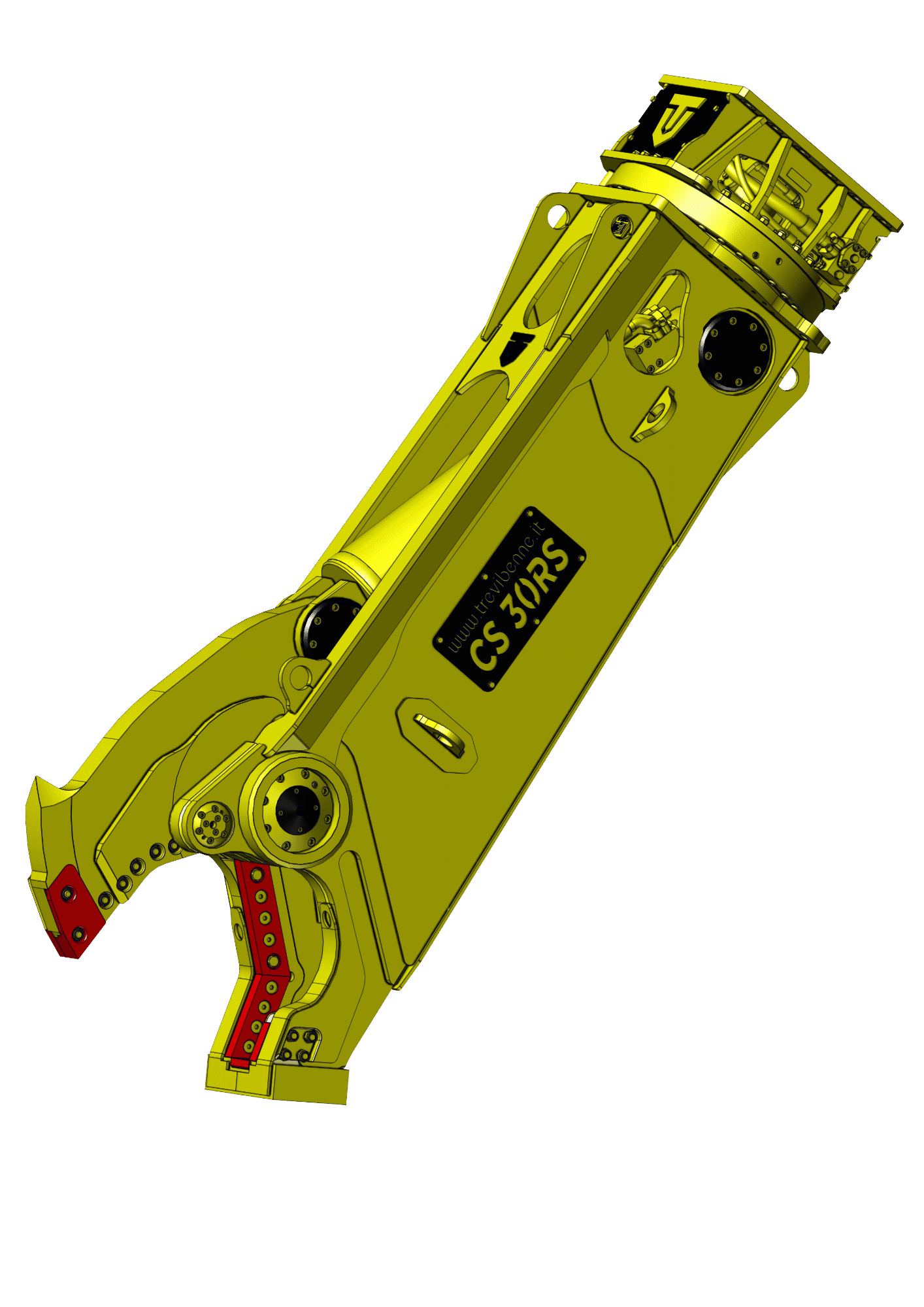

CS series (Marilyn)

Trevi Benne’s CS Series, also known as the “Marilyn” series, consists of hydraulic metal shears designed for modern industrial demolition and recycling of scrap and ferrous materials. These shears are ideal for cutting and dismantling metal structures, beams, tanks, pipes and more.

Key features and technical data

-

Robust construction: Made with a combination of Hardox 400 in the main structure and Hardox HiTuf in the jaws, ensuring durability and performance in demanding working conditions.

-

Protected cylinder barrel: The cylinder is completely protected by the frame for better protection and increased durability.

-

Fast cycle time: Equipped with a speed multiplier valve that enables faster open/close cycles, increasing productivity.

-

Adjustable and reversible blades: The blades are reversible and adjustable using shims, extending the lifetime and ensuring a precise cutting process.

-

360° rotation: The scissors are directly mounted and can rotate fully, allowing maximum flexibility during operation.

The CS series consists of 14 models covering a wide range of excavator weights from 1.5 to 310 tons, with jaw openings from 265 mm to 1,180 mm.

These metal shears are ideal for.

-

Cutting and dismantling metal buildings and structures.

-

Demolition of beams, tanks and pipes.

-

Recycling and handling of scrap and ferrous materials.

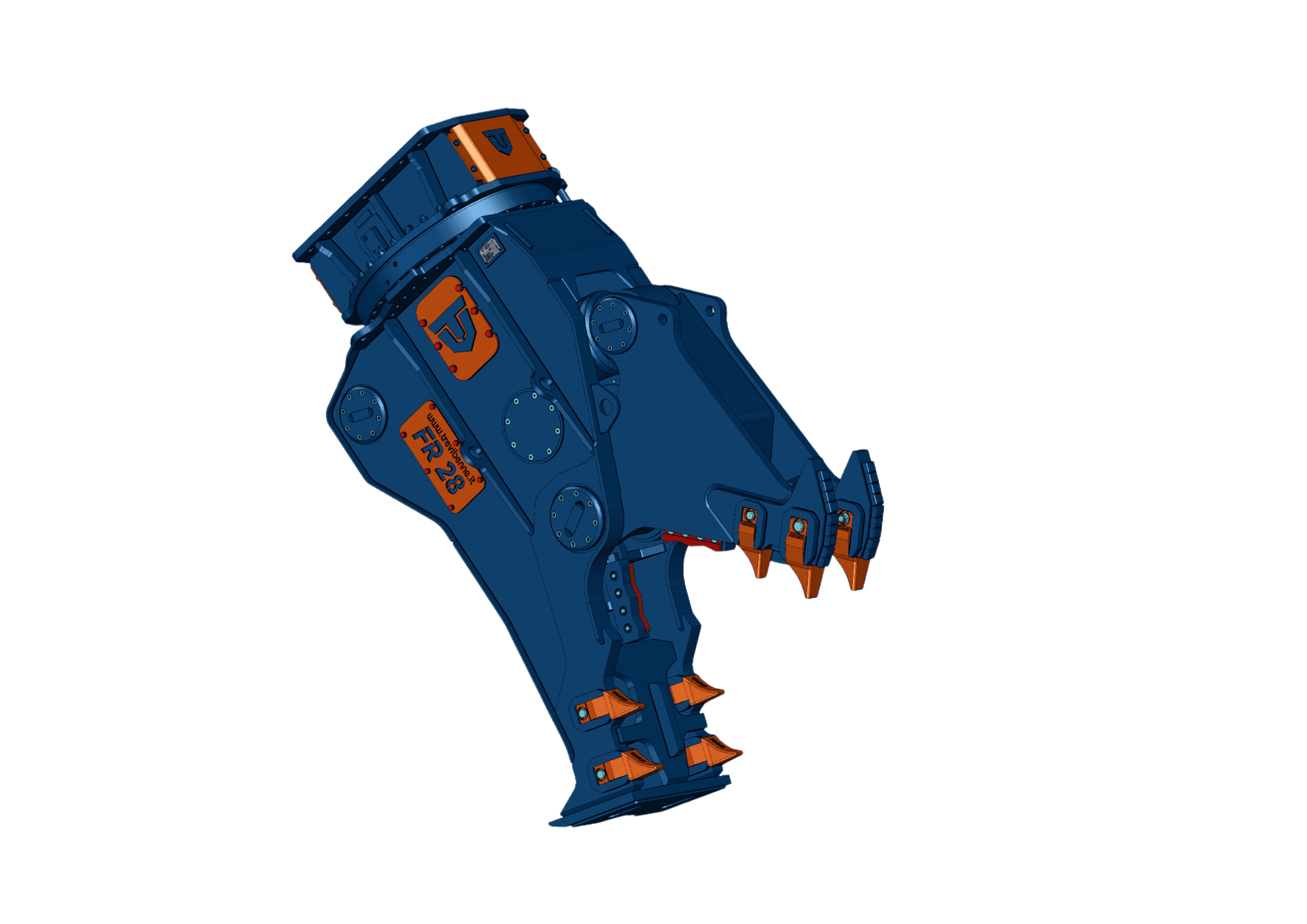

FR series

Trevi Benne’s FR series is a range of hydraulic rotary pulverizers designed for both primary and secondary demolition. These tools are designed to crush and separate reinforced concrete and other building materials efficiently.

These pulverizers are ideal for.

-

Crushing reinforced concrete.

-

Separating metal reinforcements from concrete.

-

Demolition of buildings and infrastructure.

Key features and technical data

-

Robust construction: The technical, technological and aesthetic update of the FR series has made it more “aggressive” and resistant to loads during the crushing phases.

-

Fast and productive: The speed multiplier valve makes the pulverizer extremely fast and highly productive.

-

Versatility: The structural characteristics of this pulverizer allow the operator to handle both primary and secondary demolition phases with a single piece of equipment.

The FR series is available with or without Impact BOOSTER, depending on your needs and preferences. BOOSTER technology works by significantly increasing the working pressure, providing extra power to crush even the hardest materials. In practice, this means shorter cycle times, less fuel consumption and a more efficient demolition process.

These pulverizers are ideal for.

-

Crushing reinforced concrete.

-

Separating metal reinforcements from concrete.

-

Demolition of buildings and infrastructure.

HC series

The HC series is a range of hydraulic crushers designed for primary demolition applications where precision, speed and power are essential. The crushers are particularly suitable for demolishing reinforced concrete structures and removing materials at significant heights. They can be mounted on standard excavators and high-reach demolition booms.

Key features and technical data

-

Replaceable teeth – for optimal cutting performance and easy maintenance.

-

Reversible cutting blades – extends the lifetime of cutting elements and reduces operating costs.

-

Continuous hydraulic rotation – ensures full freedom of movement and precise positioning during demolition.

The HC series is available with or without Impact BOOSTER, depending on your needs and preferences. BOOSTER technology works by significantly increasing the working pressure, providing extra power to crush even the hardest materials. In practice, this means shorter cycle times, less fuel consumption and a more efficient demolition process.

The Trevi Benne HC series combines compact design with high performance, making it one of the most precise and powerful crushers on the market.

F-series

Trevi Benne’s F-Series is a range of hydraulic solid pulverizers designed for secondary demolition phases on the ground. These tools are ideal for crushing concrete and separating rebar, making them indispensable in precision demolition projects.

Key features and technical data

-

Unique “hook” shape: This shape makes the pulverizer extremely versatile for use on the ground, enabling demolition of boundary walls, vertical cement structures of medium height, pavements and slabs with subsequent separation of rebar from concrete.

-

Interchangeable front penetration teeth: Two interchangeable front teeth ensure efficient work in the secondary demolition phase on the ground.

-

Reversible cutting blades: These blades extend tool life and reduce operating costs.

-

Speed multiplier valve: This feature ensures faster work cycles, increasing productivity.

The F-Series is available with or without the optional Impact BOOSTER, depending on your needs and preferences. BOOSTER technology works by significantly increasing the working pressure, providing extra power to crush even the hardest materials. In practice, this means shorter cycle times, less fuel consumption and a more efficient demolition process.

For additional efficiency, the F-Series is available with an integrated lifting magnet. This feature allows rebar to be picked up and removed directly after separation from the concrete. This means that the operator can work faster as the steel can be removed from the work area without the need for additional machinery.

The Trevi Benne F-Series combines power and precision, making it one of the most efficient solutions for secondary demolition.

Sorting grab

Trevi Benne’s PMZ series is a range of hydraulic sorting and demolition grapples designed for both demolition of medium-sized structures and handling and sorting of various materials. These grapples are ideal for selective demolition, material handling on construction sites and in recycling centers.

-

Demolition: Suitable for primary demolition of buildings with low consistency and resistance.

-

Material sorting: Efficient for selective sorting and loading of materials on site.

-

Recycling: Handling inert materials in recycling centers.

Key features and technical data

-

Robust construction: Made of durable material to withstand demanding working conditions.

-

Different models: Available in 10 models to fit excavators from 3.5 to 67 tons.

-

Opening width: The grapples have an opening width from 1,400 mm to 2,800 mm, enabling the handling of different material sizes.

-

Hydraulic rotation: Equipped with continuous hydraulic rotation for precise positioning during work.

-

Replaceable blades: Bolt-on reversible blades for easy maintenance and extended lifetime.

The PMZ series also offers the option of customizing the grapple shells.

-

C version: Standard with closed ribs.

-

S version: Available on request with open ribs.

Buckets for excavators

Trevi Benne’s high performance buckets are designed to move soil and materials in construction projects. These buckets are specifically designed to maximize productivity by enabling fast and efficient excavation and material handling. Their durable construction makes them suitable for working in tough conditions, minimizing downtime and maintenance.

-

Robust construction: Made from durable materials to withstand demanding working conditions.

-

Flexibility: Available in different sizes and capacities to meet specific needs.

-

Customization options: Customization options available to ensure optimal fit and functionality.

To find the right bucket, we recommend you get in touch with us so we can have a dialog about your specific needs.