Fire

Trennso technology

Trennso-Technik is a leading German company specializing in the development of technology for precise and efficient dry sorting and separation. With over 30 years of experience in the industry, Trennso is known for its highly developed machines, including screening machines, separation tables and air screens that efficiently process and separate materials such as metals, plastics and glass from complex waste streams. The company focuses on optimizing the utilization of resources and creating solutions that can be integrated into both recycling facilities and industrial productions.

Trennso’s products are characterized by their modular design and flexibility, allowing customers to tailor their systems to specific needs. With technologies such as the advanced TTS (separation table) and SIK screening machine, Trennso-Technik can ensure that even small and complex fractions can be separated efficiently, increasing the purity and quality of the recycled materials. The different systems make it possible to handle everything from non-ferrous metals and plastics to glass and compost in a single, optimized flow.

Trennso-Technik is a trusted supplier for companies looking to maximize resource recovery and reduce costs in their recycling processes.

Separation table (TTS)

TRENNSO-TECHNIK’s separation table TTS is designed to efficiently separate a wide range of bulk materials based on their specific weight and shape. This machine uses a dry separation process using clean air, making it ideal for processing free-flowing materials with limited moisture content.

Key features and technical data

The TTS separation table is suitable for a variety of applications, including.

-

Recycling: Separating materials such as metals, plastics and glass based on their density.

-

Food industry: Cleaning grains, nuts and other agricultural products by removing impurities.

-

Bulk materials: Processing minerals and other raw materials to obtain uniform product fractions.

How does the technology work?

-

Material feed: The material to be separated is fed in via an inlet channel and distributed evenly over the work area.

-

Vibrating work surface: The work surface is driven by an eccentric motor and its inclination can be adjusted to optimize separation.

-

Airflow: A pressure blower under the work surface pushes air through the material, fluidizing the lighter particles and separating them from the heavier ones.

-

Separation: Depending on the movement, inclination and airflow of the work surface, the heavier particles are transported upwards towards the heavy fraction outlet, while the lighter particles move downwards towards the light fraction outlet.

Depending on the specific application or the wear resistance of the material, TRENNSO-TECHNIK offers different versions of machine wear parts, such as HARDOX, PU or stainless steel. In addition, complete stainless steel constructions and surface treatments are available on demand.

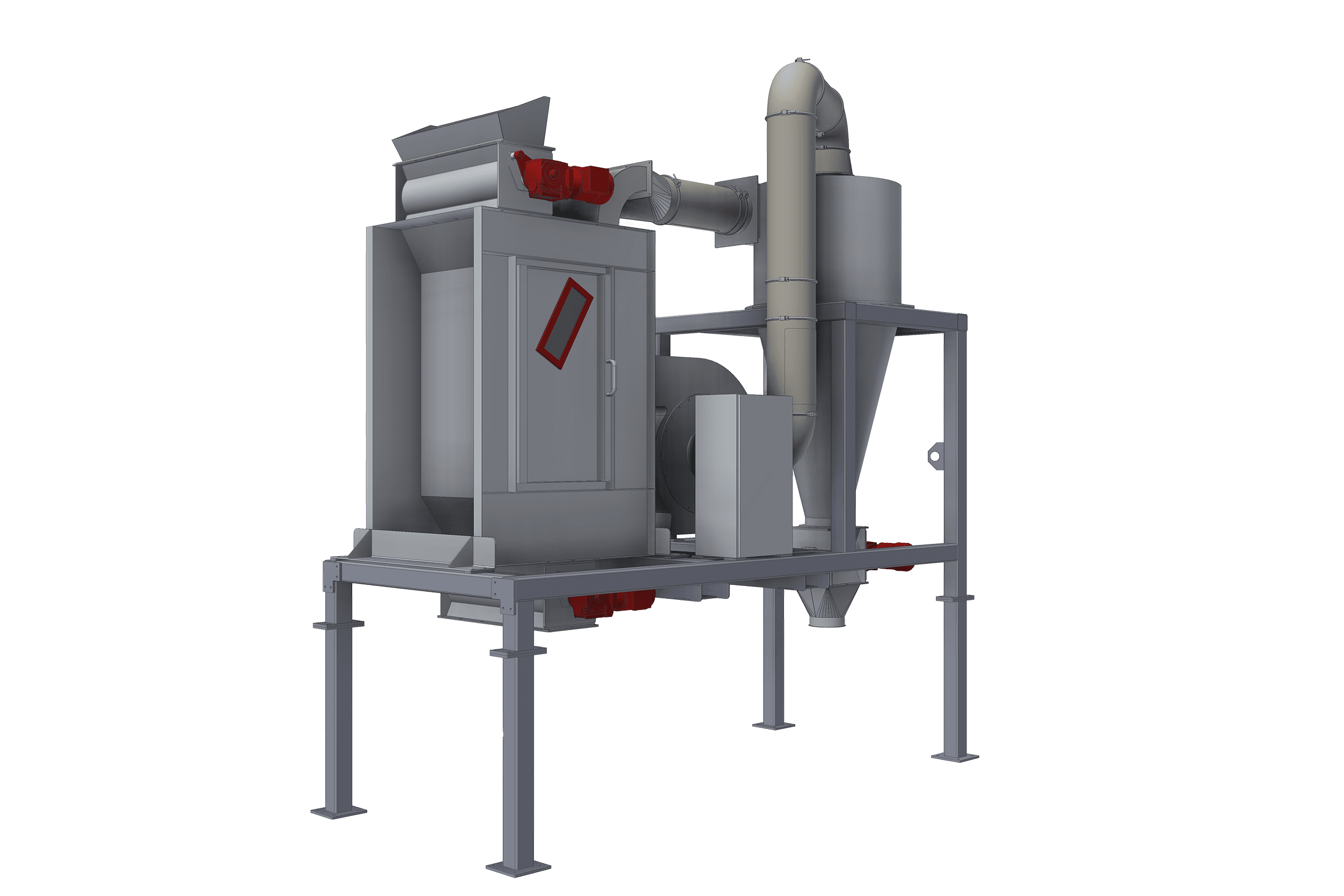

Windscreen (ZZS)

TRENNSO-TECHNIK’s Zig-Zag Sifter (ZZS) is an advanced air classifier designed to separate bulk materials based on their specific weight, shape and size. This technology uses a zigzag-shaped channel where the materials are exposed to an upward airflow, enabling efficient separation of light and heavy fractions.

How does the technology work?

-

Material feed: Material is fed into the zigzag classifier via a rotating valve and distributed evenly over the entire cross-section of the channel.

-

Airflow: A blower generates an upward airflow that passes through the classifier from bottom to top, flushing and separating the bulk material.

-

Separation: At each bend in the grading channel, the product must pass through the airflow and then encounters the opposite channel wall. During this process, higher density materials sink downwards in the channel due to gravity, while lighter materials are sucked upwards by the airflow.

Application areas:

ZZS is suitable for a wide range of applications, including.

-

Recycling: Separating materials such as plastics, paper and metals based on their density and shape.

-

Food industry: Cleaning grains, nuts and other agricultural products by removing light impurities such as shells and dust.

-

Building materials: Sorting sand, gravel and other building materials by size and weight.

-

Adjustable airflow: The air speed can be adjusted using a frequency converter, allowing precise control over the separation process.

-

Flexible operation: The air classifier is depth adjustable and can operate in both extraction and recirculation modes, depending on specific process requirements.

-

Efficient air filtration: The extracted air is cleaned using a downstream filter system or cyclone separator, ensuring environmentally friendly operation.

-

Customization options: Depending on the abrasiveness of the material, TRENNSO-TECHNIK offers different wear linings, such as HARDOX, PU, stainless steel or ceramic linings, to extend the life of the machine.

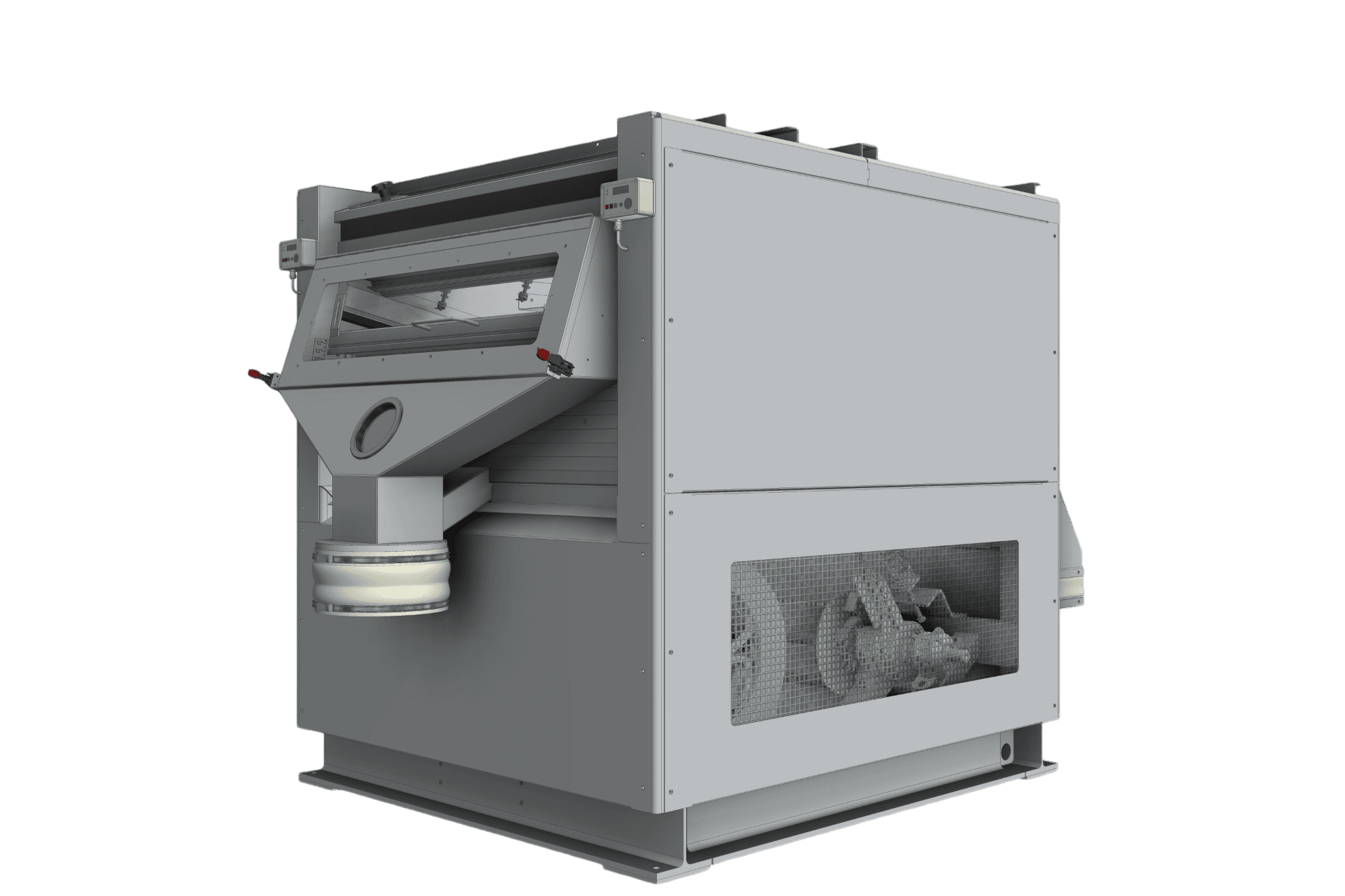

Wind sieve (QSS)

TRENNSO-TECHNIK’s QSS screen is designed to separate coarse bulk materials based on their specific weight, shape and size. The material is fed into the screen’s hopper via a vibrating distribution chute, which ensures an even distribution over the entire cross-section of the screen. A blower generates a horizontal airflow that passes through the screen and separates the materials by weight.

-

Heavy fractions sink quickly due to their greater weight and are discharged via a separate outlet.

-

Medium-heavy products are diverted by the horizontal airflow and discharged through another channel.

-

Light fractions are captured by the airflow and removed by aspiration.

How does the technology work?

The separation process is controlled by air valves, adjusting the air injection funnel and regulating the air flow. The wind screen can operate in both extraction mode and air recirculation mode. The extracted air is then cleaned via a downstream filter system or a cyclone separator.

Depending on material properties and abrasiveness, TRENNSO-TECHNIK offers different wear-resistant housing versions, including HARDOX, PU and stainless steel. In addition, it is possible to get a complete stainless steel construction and surface treatments according to specific needs.

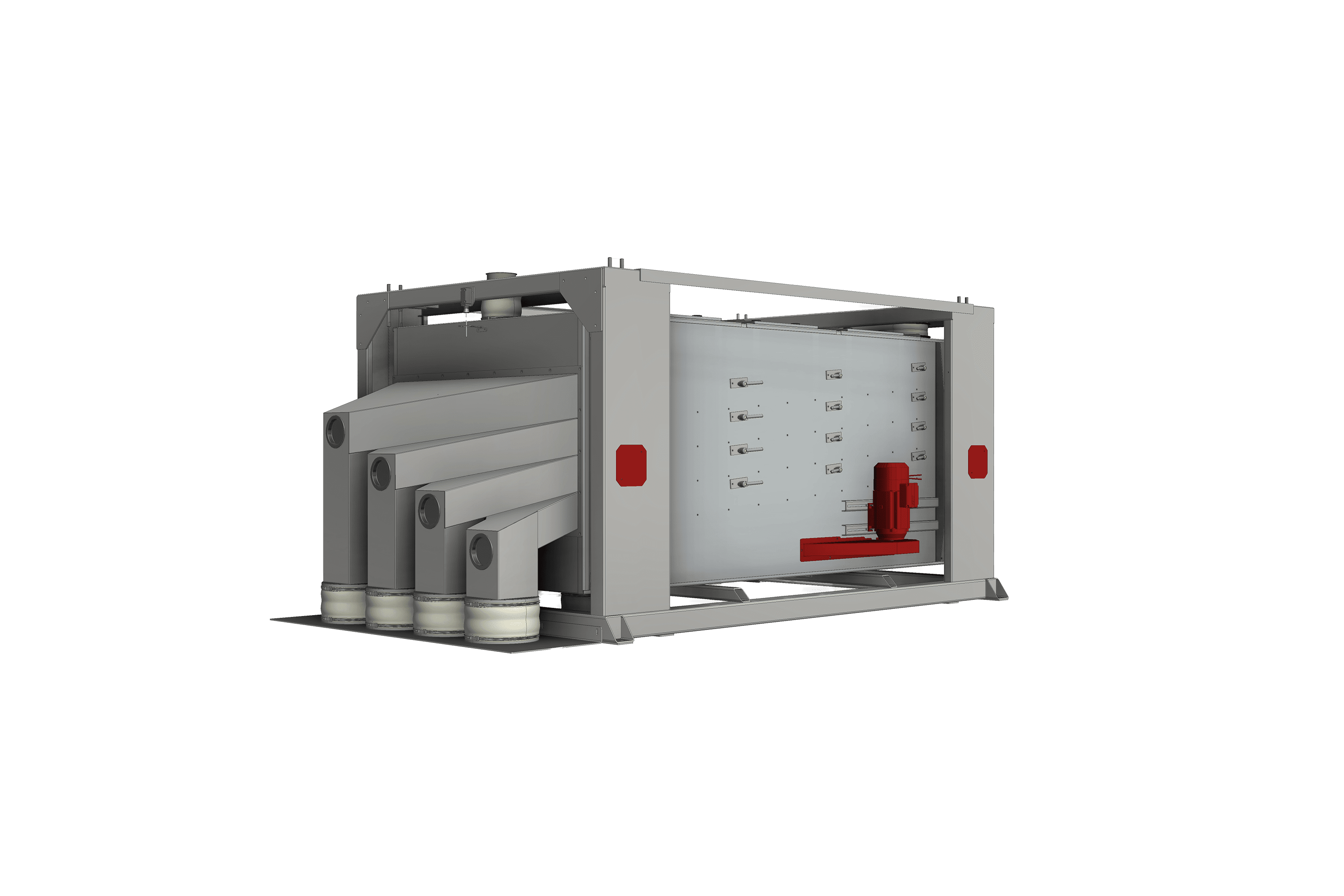

Sight (SIK)

TRENNSO-TECHNIK’s SIK screening machine is designed to efficiently sort granular and powdery materials into different grain sizes.

The machine works by feeding the material into a free-swinging screening box via a distribution unit. This box is suspended by steel wires within a robust steel frame with a dust-tight design.

The screens can be pulled out from the front and the length of the screening layer is divided into segments, minimizing space requirements when changing screening surfaces.

Key features and technical data

-

Continuous sieve cleaning: A rubber ball cleaning system keeps the sieve surface free from clogging, ensuring constant efficiency.

-

Flexible cover materials: The sieve surfaces vary from perforated sheets to fine mesh fabrics, allowing customization to specific materials and requirements.

-

Adjustable operation: The electrically driven sieve box can be adjusted in angle, lift and rotation speed to achieve optimal throughput and accurate classification of material.

-

External sight outlet: As an option, the machine can be equipped with external sight sockets for excellent accessibility.

-

Aspiration connection: The machine can be connected to an aspiration system to remove dust and light particles during the sieving process.

The SIK screener is suitable for sorting free-flowing bulk materials that do not exceed a certain moisture limit. It is ideal for various industries, including the food industry and recycling sector, where precise separation of materials is essential.

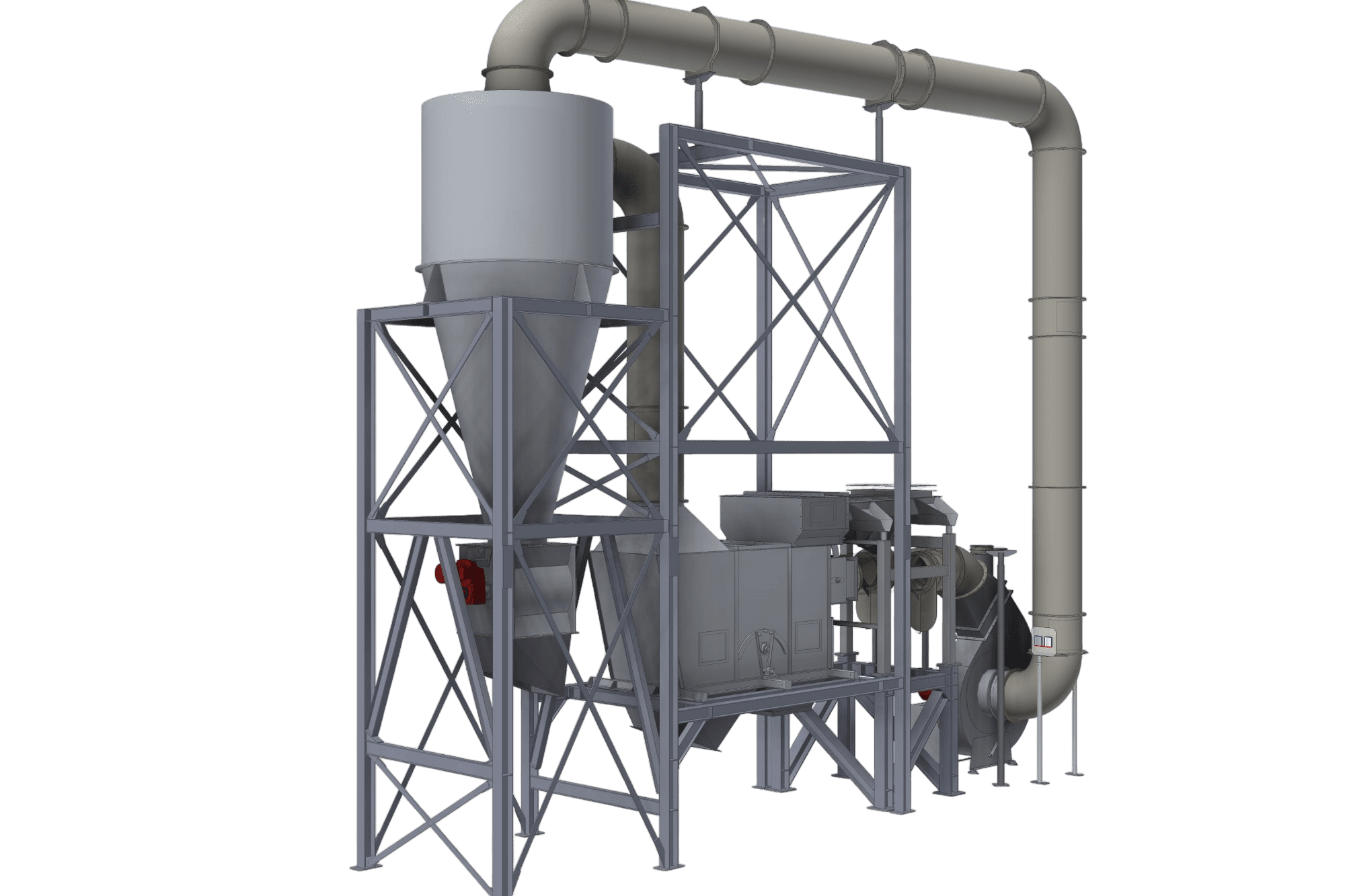

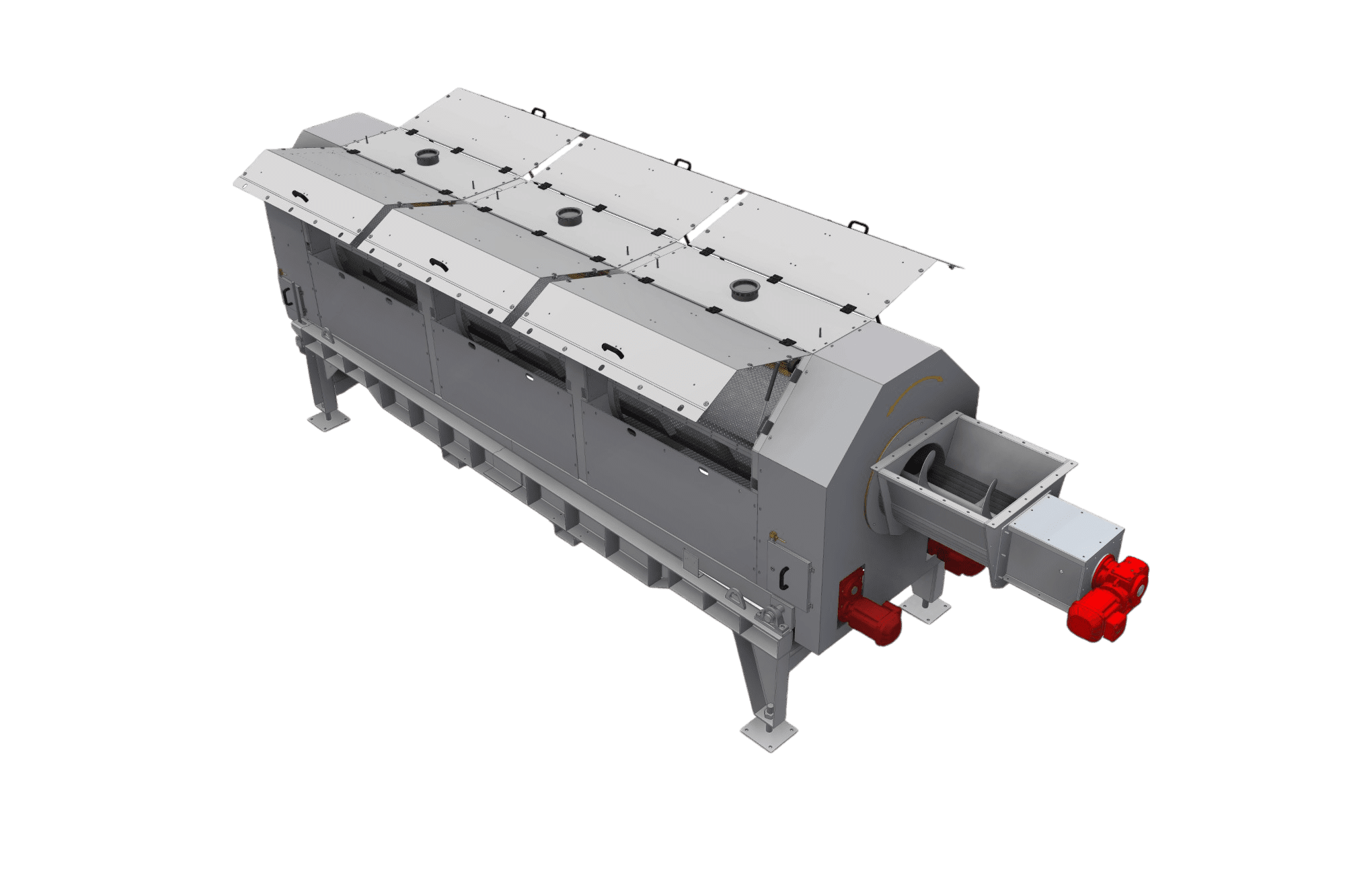

Drum sieve (TSM)

TRENNSO-TECHNIK’s Drum Screener (TSM) is designed to efficiently filter, separate and screen various materials of different sizes using a perforated drum. These machines, also known as drum screens or rotary screens, are typically used in waste, compost and recycling facilities, especially in the solid waste treatment industry.

Key features and technical data

Depending on the design, the drum screen can split the material into up to four output sizes. Easy-to-use maintenance covers on the drum screen make it easy to clean the drum, ensuring smooth operation and reducing downtime.

How does the technology work?

The material to be screened is fed into the drum screen via a feed auger, conveyor, elevator or vibrating chute. The drum perforation can vary from coarse perforated plates to fine mesh panels, allowing customization for specific screening needs. A built-in spindle then transports the material over the different screening drums.

The speed and inclination of the drum can be adjusted using a frequency converter, ensuring a customized degree of separation according to individual specifications and different material types.

Transport and dosing technology

TRENNSO-TECHNIK offers a range of conveying and dosing technologies designed for efficient handling of bulk materials. Here is an elaboration of the systems mentioned.

Elevators:

These systems enable vertical transportation of bulk materials with high efficiency and minimal waste. They are ideal for moving materials to higher levels in the production process without compromising speed or product integrity.

Auger conveyors:

Used primarily for horizontal transportation of powder or granular materials. Their closed design protects the materials from external influences and ensures a smooth and controlled material flow.

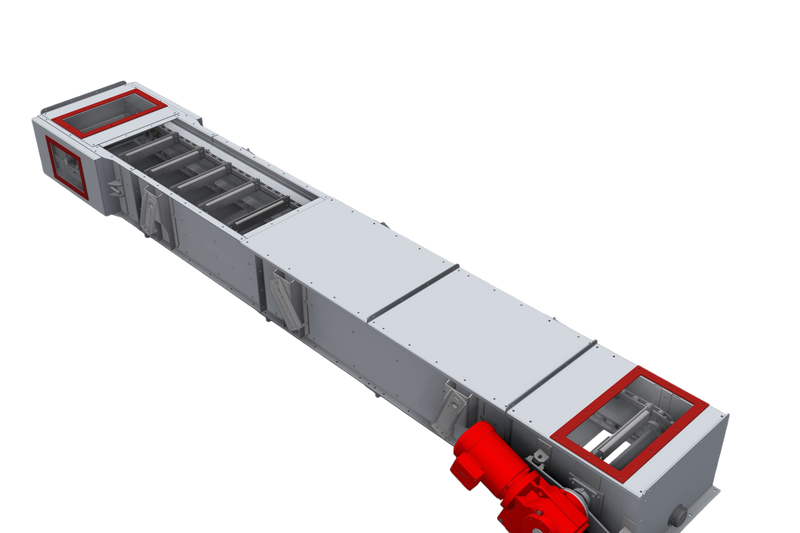

Chain conveyors:

These conveyors are designed to handle heavy and abrasive material over longer distances. Their robust construction ensures reliable operation, even in demanding conditions.

Cyclones:

These units remove dust and filter air in industrial processes. They use centrifugal force to separate particles from the airflow, resulting in a cleaner workplace and improved air quality.

Conveyor belts:

Customized systems designed to ensure a continuous material flow. They can be tailored to specific needs and are essential for the efficiency of many production lines.

Cell wheel locks:

These components are used for precise dosing and airtight transfer of materials between process steps. They ensure a constant flow of material and prevent air leaks, which is essential in many industrial processes.