Fire

Tomra

TOMRA is a Norwegian company that has been a leader in innovative solutions for sorting and resource recovery since 1972. With advanced sensor-based technologies, TOMRA helps companies around the world optimize material recycling and minimize waste. Their solutions are widely used in the recycling, food processing and mining industries, where precision and efficiency are crucial.

TOMRA’s sorting systems are designed to maximize the yield of valuable materials and improve the quality of recyclable fractions. The company offers advanced technologies such as NIR, X-ray and laser detection, ensuring accurate identification and separation of materials – from plastics and metals to complex waste streams.

With a strong global presence and a constant focus on innovation, TOMRA is recognized for its ability to deliver solutions that make resource management more efficient and sustainable. They combine technological expertise with a deep understanding of material flow, making their machines a preferred solution for companies looking to optimize their sorting processes.

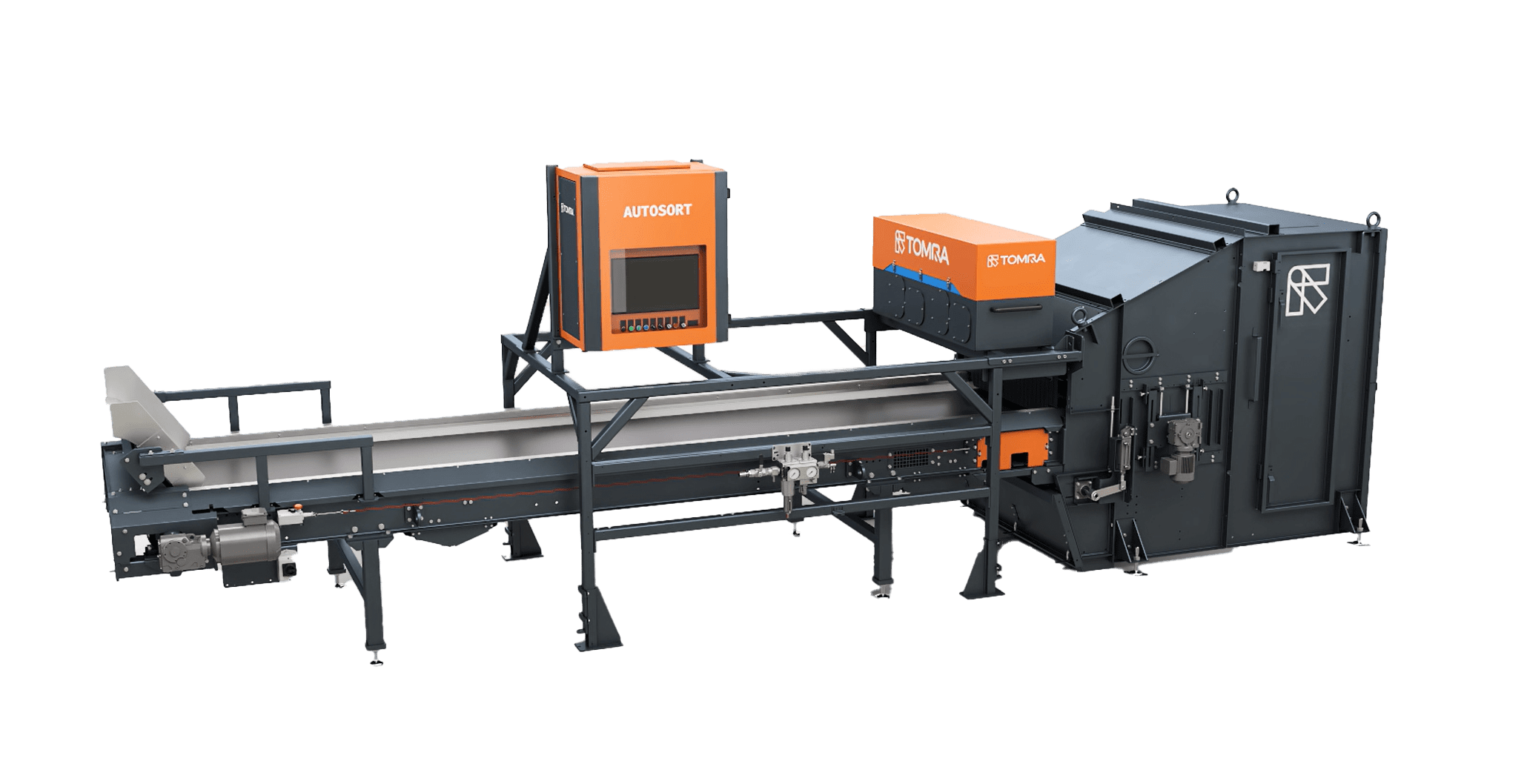

AutoSort™

AUTOSORT™ is an advanced and multifunctional sorting solution from TOMRA, designed to meet the ever-changing needs of the waste and metal recycling industry. With its compact size and flexible design, AUTOSORT™ easily integrates into existing facilities, ensuring an efficient and accurate sorting process.

Key features and technical data

AUTOSORT™ is equipped with cutting-edge technology including FLYING BEAM®, FOURLINE and DEEP LAISER, enabling exceptional material recognition and sorting accuracy. The system offers high sorting capacity with low energy consumption and requires minimal maintenance, resulting in reduced operating costs.

The exact technical specifications, such as capacity and dimensions, may vary depending on the specific configuration and application.

How does the technology work?

AUTOSORT™ uses a combination of advanced sensor technologies to identify and sort materials based on their spectral properties.

As materials are transported on the belt, they are illuminated by FLYING BEAM® technology, ensuring consistent and reliable detection. DEEP LAISER technology analyzes the surface structure and composition of the materials, enabling precise differentiation between different material types. This results in an efficient separation of recyclable materials from the waste stream.

Value creation

The implementation of AUTOSORT™ in sorting processes brings significant benefits. The high accuracy of material separation increases the purity of the recovered materials, improving their market value. The compact and flexible design enables easy integration into existing facilities without the need for extensive remodeling. Furthermore, the system’s energy efficiency and low maintenance requirements contribute to reduced operating costs, improving overall profitability.

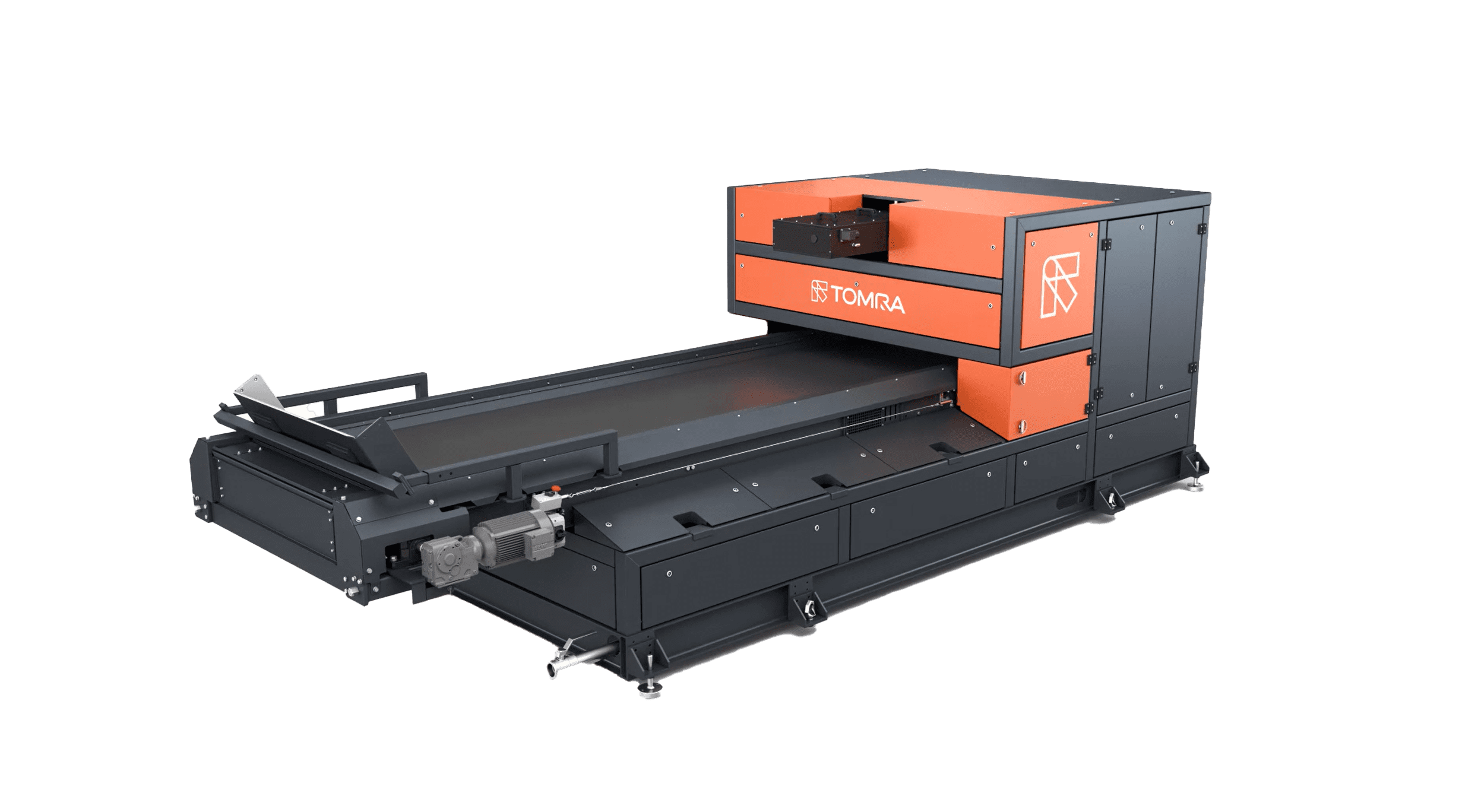

AutoSort™ Flake

AUTOSORT™ FLAKE is an advanced optical flake sorting machine from TOMRA, designed to achieve maximum purity in plastic recycling processes.

Key features and technical data

AUTOSORT™ FLAKE combines powerful NIR spectrometers, full-color cameras and metal sensors to ensure outstanding sorting performance. Its high-speed valves separate even the smallest contaminants with maximum precision to meet extremely high purity requirements.

How does the technology work?

AUTOSORT™ FLAKE uses a combination of sensor technologies to identify and sort plastic flakes based on material, color and metal content. As the flakes pass through the machine, they are illuminated by an integrated light source, ensuring stable sorting performance and minimal downtime. Its highly sensitive electromagnetic sensor detects even the smallest non-ferrous and ferrous metals (as small as 1 mm) such as aluminum springs and copper wires.

Value creation

The implementation of AUTOSORT™ FLAKE in plastic recycling processes leads to significant benefits.

The high accuracy of material separation increases the purity of the recovered plastic flakes, improving their market value and making them suitable for high-end applications like bottle-to-bottle recycling. Furthermore, the system’s energy efficiency and low maintenance requirements contribute to reduced operating costs and improved overall profitability.

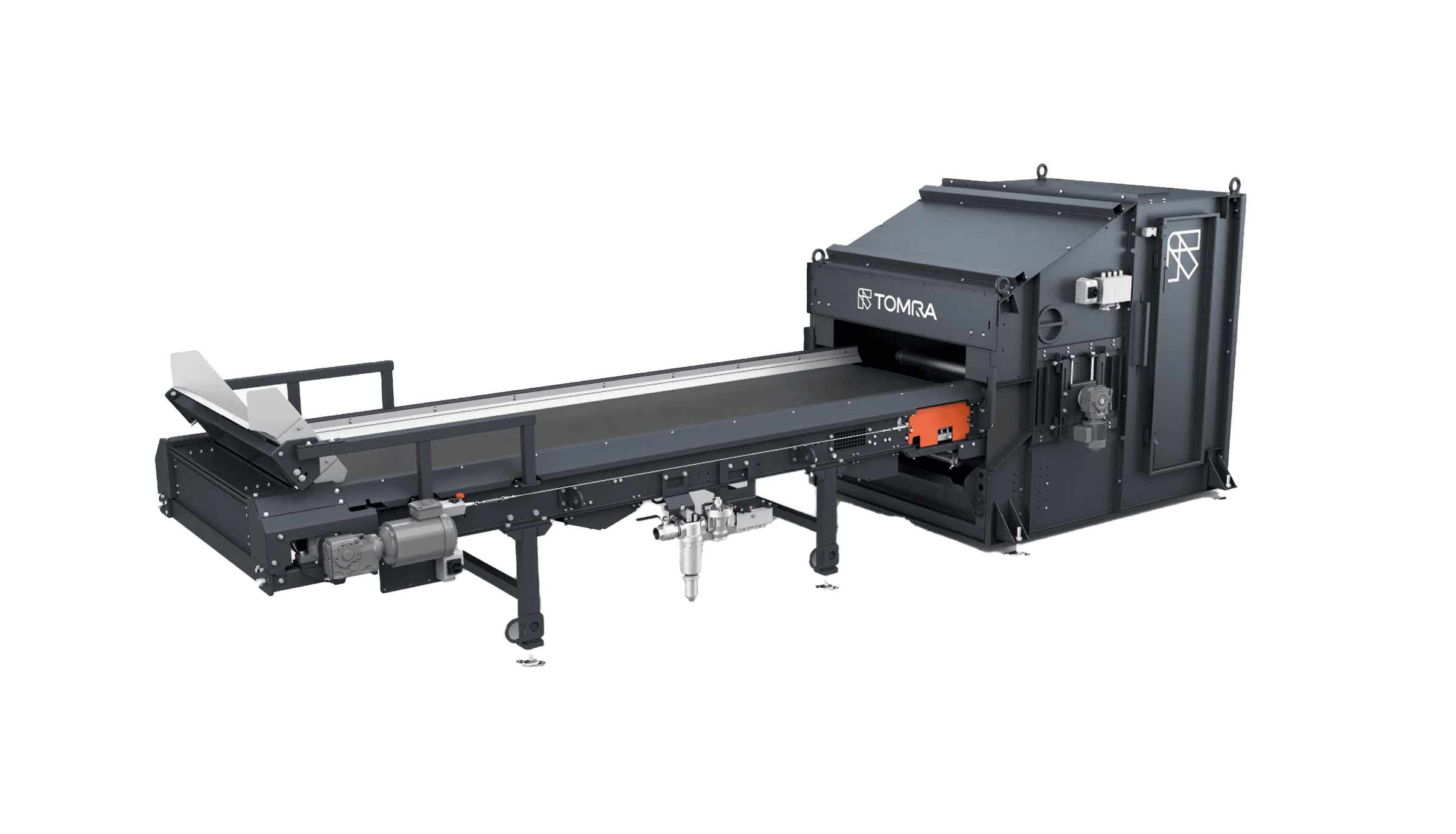

AutoSort™ Speedair

AUTOSORT™ SPEEDAIR is an advanced sorting solution from TOMRA, designed to stabilize lightweight materials such as plastic film and lightweight packaging on high-speed conveyors. This enables increased recycling speed and improved cleanliness without unnecessary downtime.

Key features and technical data

Closed laminar airflow: Stabilizes light objects on the conveyor belt using speed-controlled, fan-driven air inlets, ensuring a constant airflow over the belt and preventing material displacement.

High throughput: Supports belt speeds up to 6 m/s, increasing capacity and maintaining high output quality.

Open conveyor system without a hood: Reduces the risk of material blockages and enables faster maintenance compared to traditional high-speed systems.

Efficient FLYING BEAM™ technology: Improves light efficiency, resulting in higher performance and lower operating costs.

How does the technology work?

AUTOSORT™ SPEEDAIR uses a closed, fan-driven airflow to stabilize lightweight materials on a high-speed conveyor belt. This ensures accurate identification of valuable materials and removal of impurities. The open, hoodless conveyor design minimizes the risk of material blockages and reduces machine downtime.

Value creation

Implementing AUTOSORT™ SPEEDAIR in recycling processes offers significant benefits:

- Increased throughput: Higher belt speeds enable processing of larger volumes of material, improving productivity.

- Improved purity: Precise sorting results in higher quality recycled materials, increasing their market value.

- Reduced operating costs: Efficient air management and FLYING BEAM™ technology lead to lower installation and operating costs.

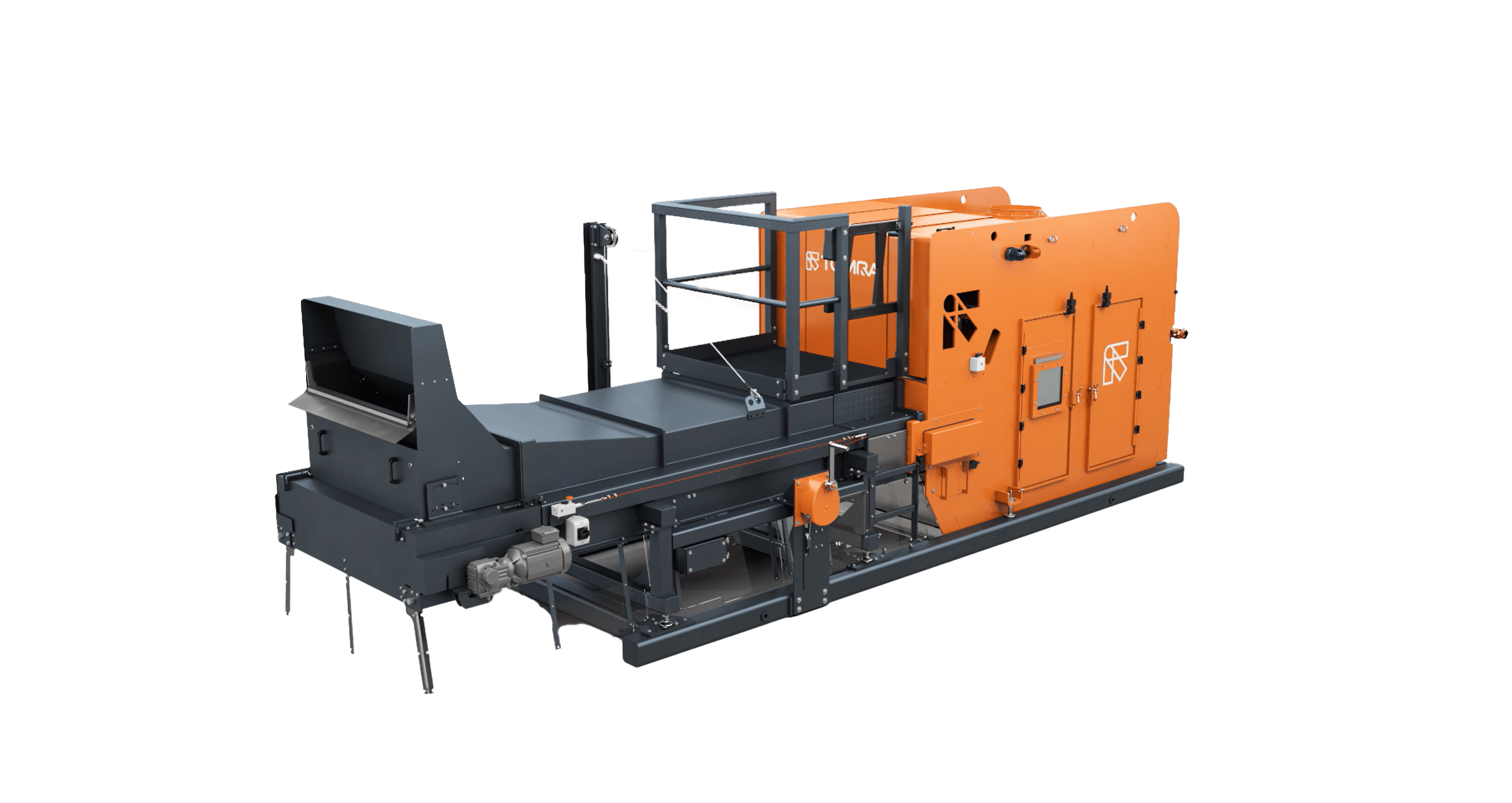

CombiSense™

COMBISENSE™ is an advanced sorting machine from TOMRA, designed to precisely sort non-ferrous metals based on color. This technology enables efficient extraction of valuable materials such as zinc, copper, brass, electronic scrap and printed circuit boards from mixed waste streams.

Key features and technical data

COMBISENSE™ combines several advanced technologies to ensure optimal sorting performance. It is equipped with FLUIDCOOL™ LED technology that maintains a constant temperature and uniform light distribution, ensuring long-term sorting stability. Its Dual Processing Technology simultaneously processes object and area information to quickly identify specific materials on the conveyor belt.

With a capacity of up to 5 metric tons per hour, COMBISENSE™ is ideal for high-speed sorting of metals such as zinc, copper and brass. The flexible multi-sensor sorter can also be programmed to create fractions for wires, coins and non-metallic materials like plastics.

How does the technology work?

COMBISENSE™ uses a high-resolution CRGB color camera combined with electromagnetic metal detection to accurately identify and separate non-ferrous metals from mixed waste streams. As materials move along the acceleration belt, the system analyzes their color and material properties in real-time, enabling accurate sorting of even small and complex fractions.

Value creation

Implementing COMBISENSE™ in recycling processes brings significant benefits. The precise sorting increases the purity of the recovered metals, improving their market value.

The high throughput capacity and ability to handle different grain sizes and material types increases operational efficiency. Furthermore, the system’s automatic adjustment of the separation system and long-term sorting stability ensure a high return on investment over time.

If you work with recycling non-ferrous metals such as zinc, copper, brass or electronic scrap, COMBISENSE™ can take your waste treatment to the next level.

Finder™

FINDER™ is an advanced sorting machine from TOMRA, designed to accurately recover non-ferrous metals from complex material streams. By combining electromagnetic sensors with built-in machine intelligence, FINDER™ can effectively detect and sort metals regardless of material complexity or grain size.

Key features and technical data

FINDER™ is equipped with cutting-edge technologies like SUPPIXX™ spatial resolution and DEEP DATA™ systems that ensure high throughput and purity levels. The intelligent object recognition enables multifunctional sorting and the intuitive user interface makes operation simple.

The machine’s modular and flexible design, combined with high-precision valve blocks, makes it ideal for various sorting applications in metal and waste recycling.

How does the technology work?

FINDER™ uses a unique combination of sensor technologies to identify metals in complex material flows. As the material moves along the conveyor belt, the electromagnetic sensors detect the presence of metals and the machine’s intelligent systems analyze the data to determine the composition of the material.

The high-precision valve blocks then ensure accurate separation of the desired metal fractions, resulting in high purity and yield.

Value creation

The implementation of FINDER™ in recycling processes brings significant benefits.

The high precision in metal recognition and sorting increases the purity of the recovered materials, improving their market value. The high throughput capacity and flexibility in handling different material types and grain sizes increases operational efficiency. Furthermore, the system’s advanced technologies and intuitive user interface ensure reduced operational complexity and lower costs.

X-TRACT™ for Metal

X-TRACT™ is an advanced sorting solution from TOMRA, designed to maximize the recycling of aluminium using X-ray sorting technology (XRT). This technology separates aluminum from heavy metals in a single process, ensuring high purity and efficiency in the recycling process.

Key features and technical data

X-TRACT™ is equipped with a new generation of DUOLINE™ sensors that improve stability and extend lifetime. The machine supports high throughput with belt speeds up to 3.8 m/s, enabling efficient sorting of complex material flows. The advanced software intelligence and flexible operation options make it possible to adapt the system to different sorting tasks and grain sizes.

How does the technology work?

X-TRACT™ uses dual-energy X-ray transmission (XRT) to detect and separate objects based on their atomic density. The machine’s top-down design protects the X-ray source from dust and dirt, reducing maintenance costs. The optimal placement of the source in relation to the sensor ensures more accurate detection and higher throughput.

Value creation

The implementation of X-TRACT™ in recycling processes brings significant benefits.

The high precision in separating aluminum from heavy metals increases the purity of the recovered materials, improving their market value. The high throughput capacity and flexibility in handling different material types and grain sizes increases operational efficiency. Furthermore, the system’s advanced technologies and intuitive user interface ensure reduced operational complexity and lower costs.

If you work with aluminum recycling and want to achieve the highest purity in your products, X-TRACT™ can take your waste treatment to the next level.

GAINnext™

GAINnext™ is an advanced sorting solution from TOMRA that uses deep learning technology to maximize the recovery and purity of valuable materials in the waste and metal recycling industry. This AI-powered sorting machine is designed to identify and sort complex material flows with high precision and efficiency.

Key features and technical data

GAINnext™ is equipped with a high-resolution color camera and integrated deep learning software that enables visual classification of thousands of objects in milliseconds. This system can process up to 2,000 separations per minute, depending on the application, ensuring high throughput and efficient sorting.

The integrated deep learning technology makes it possible to identify hard-to-classify objects, reducing the need for manual sorting and enabling automation of complex tasks that traditional optical sorting systems cannot handle.

How does the technology work?

GAINnext™ uses deep learning technology based on artificial neural networks trained to recognize and classify objects in complex material flows. As materials move along the sorting line, the system quickly and accurately identifies different material types based on their visual properties.

This advanced object recognition makes it possible to sort materials that previously required manual intervention, increasing the efficiency and accuracy of the sorting process.

Value creation

The implementation of GAINnext™ in recycling processes brings significant benefits.

The high accuracy of material recognition and sorting increases the purity of the recovered materials, improving their market value. The automation of complex sorting tasks reduces the need for manual sorting, lowering operating costs and increasing operational efficiency. Furthermore, GAINnext™ enables the processing of multiple material streams on a single sorting line, increasing the flexibility and adaptability of the recycling plant.