Steinert is a German company that has been known for its innovative solutions in sorting and separation for more than 130 years. The company specializes in magnetic separation and sensor-based sorting systems, which are widely used in the recycling and mining industries. Their technology ensures a high level of material recovery and purification, making them one of the most respected players in the market.

Steinert’s sorting systems are used to maximize the recovery of valuable materials such as metals, which is crucial in metal recycling, mining and municipal waste treatment. Their advanced solutions include magnetic separators for the recovery of ferrous and non-ferrous metals and sensor-based systems such as X-ray and NIR sorting that can identify and separate materials with extreme precision.

The company is recognized globally for its ability to provide solutions that improve the efficiency and quality of material handling. They combine tradition with advanced technology, making their machines highly reliable and energy efficient, while delivering high performance in demanding environments.

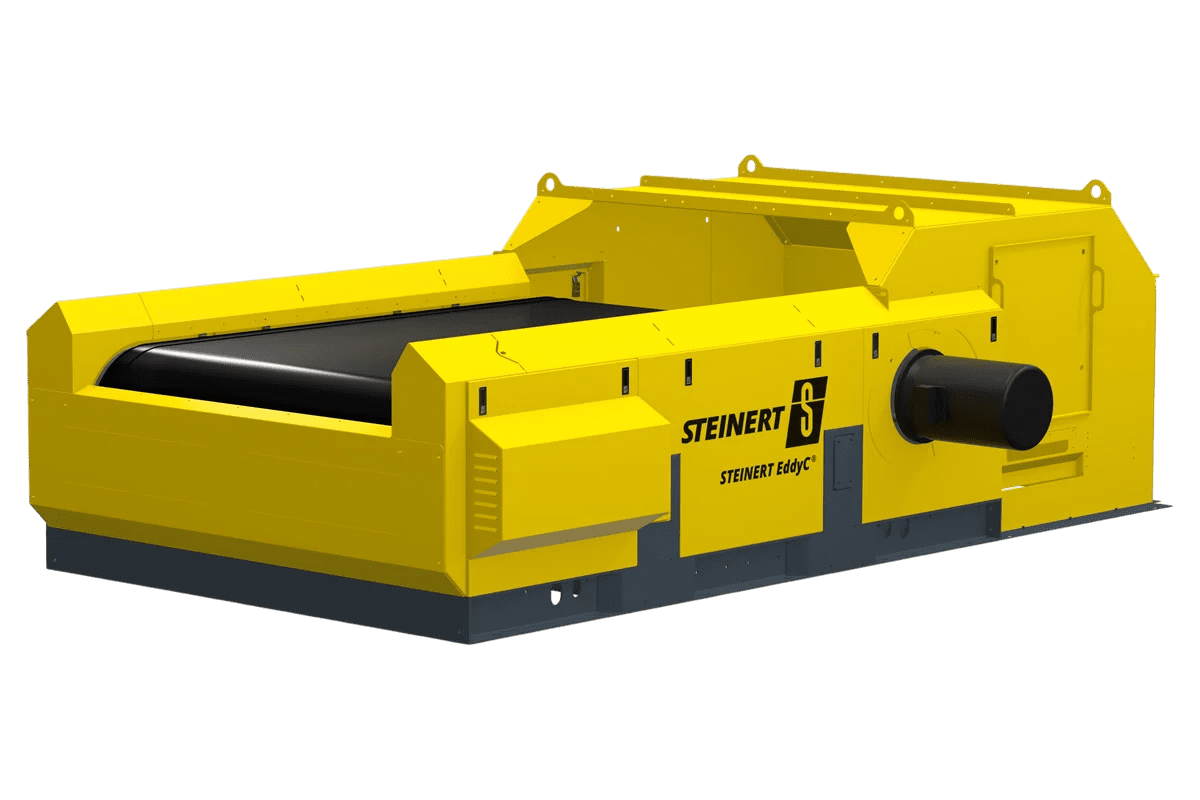

STEINERT NES - Eddy Current Separator

STEINERT EddyC® is an advanced eddy current separator designed to efficiently separate non-ferrous metals from different material streams. This technology is essential in the recycling industry to maximize the recovery of valuable metals such as aluminum, copper, zinc and brass.

Key features and technical data

The STEINERT EddyC® is equipped with an eccentric pole system that ensures optimal separation efficiency.

The machine’s self-supporting frame design enables quick change of the conveyor belt in just 10 minutes, significantly reducing maintenance time.

In addition, the machine offers variable adjustment of the application point of the pole system, making it possible to adapt the separation to different material types and grain sizes.

The STEINERT EddyC® is available in different versions with working widths from 500 mm to 2,500 mm, making it suitable for a wide range of applications.

How does the technology work?

STEINERT EddyC® uses a rapidly rotating permanent magnet system in the outlet drum that generates high-frequency alternating magnetic fields. These fields induce strong eddy currents in the conductive non-ferrous metal parts, creating their own magnetic fields that oppose the external fields. This interaction results in the non-ferrous metals being deflected from the remaining material flow, enabling efficient separation. The eccentric pole system ensures that the influence of the magnetic field is greatest at the moment of separation, improving precision and reducing wear on the conveyor belt and drum shell.

Value creation

Implementing STEINERT EddyC® in recycling processes brings significant benefits. The high separation efficiency increases the purity of the recovered non-ferrous metals, improving their market value. The robust construction and innovative design reduces maintenance costs and minimizes downtime. In addition, the machine’s flexibility in adjusting and adapting to different material types enables an optimized recycling process, resulting in higher overall efficiency and profitability.

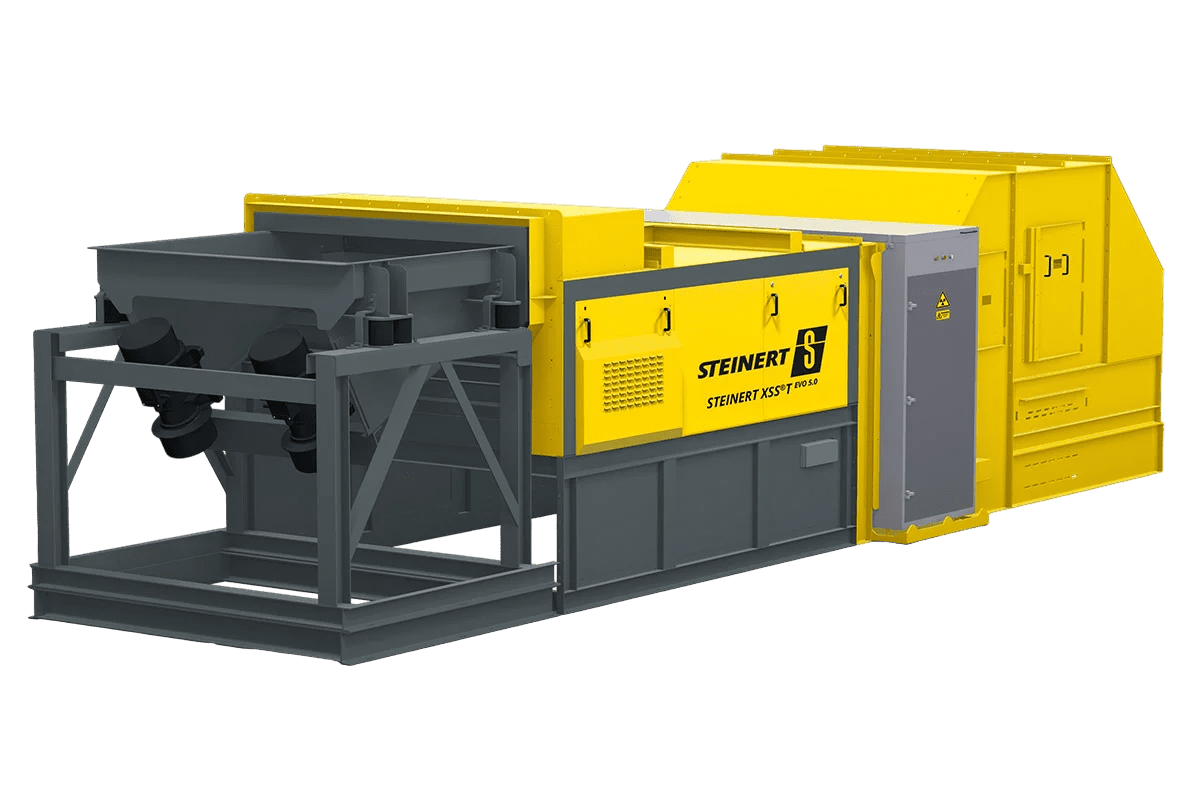

STEINERT XSS T EVO 5.0 - X-ray sorting

STEINERT XSS® T EVO 5.0 is an advanced X-ray sorting machine designed for dry density sorting of bulk materials. This technology uses dual-energy X-ray transmission to detect materials based on their density, enabling efficient separation of different material types.

Key features and technical data

STEINERT XSS® T EVO 5.0 is equipped with Multilayer Data Evaluation (MDE), which handles complex sorting tasks such as magnesium detection and composite object identification. Automatic X-ray monitoring (AXM) ensures consistently high detection and sorting quality by continuously calibrating the X-ray sensors.

Furthermore, the machine is designed with automatic cleaning of the X-ray area (Auto X clean), reducing the need for manual cleaning and ensuring reliable detection.

How does the technology work?

STEINERT XSS® T EVO 5.0 uses X-ray transmission to measure the absorption of X-rays by materials at two different energy levels. This dual-energy method compensates for the thickness of the object and determines the specific absorption of the material, revealing its density.

Materials are transported on a vibrating belt through the scanning area, with the X-ray source located below the belt. Detectors above the belt measure the unabsorbed radiation, enabling classification and sorting based on density classes.

Value creation

Implementing STEINERT XSS® T EVO 5.0 in sorting processes brings significant benefits.

The precise density sorting improves the purity of the recycled materials, increasing their market value. The automatic calibration and cleaning reduces maintenance costs and ensures stable operation. In addition, the machine’s high resolution valve clearance enables efficient processing of fine materials, increasing the overall efficiency and profitability of the sorting process.

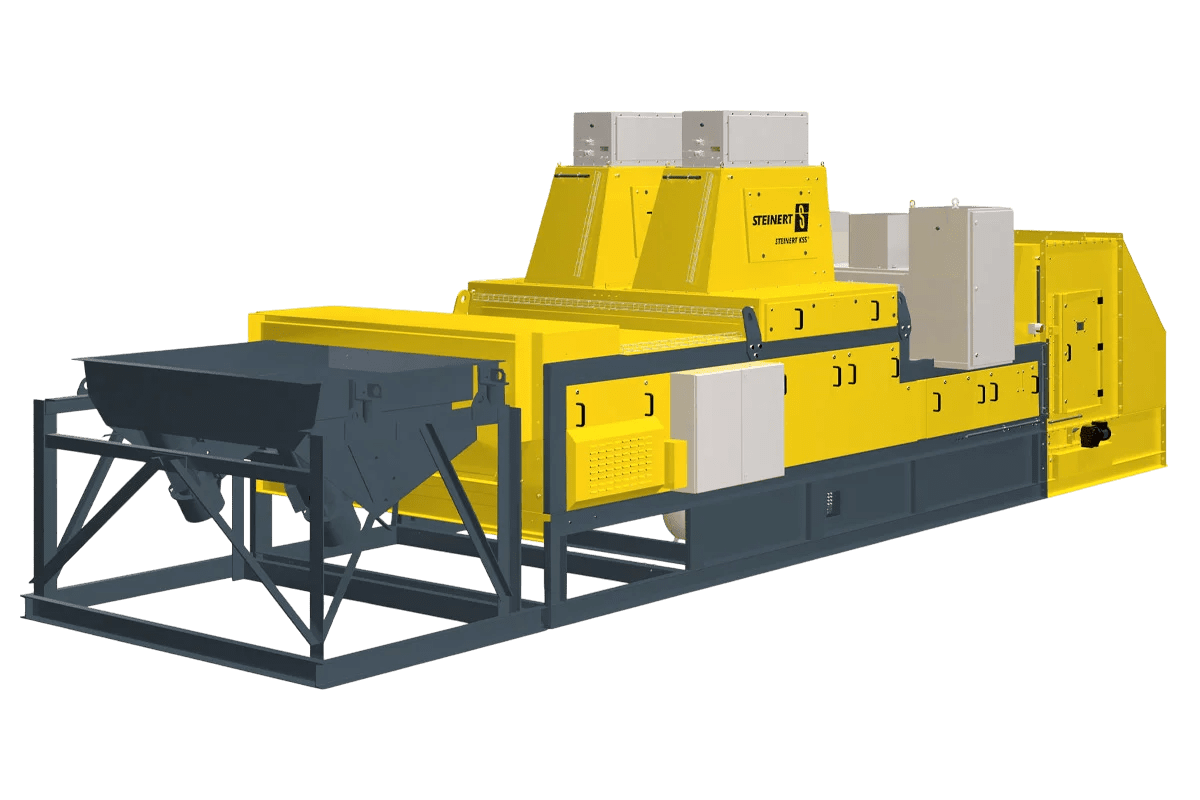

STEINERT KSS - Combined sensor-based sorting

The STEINERT KSS | XF CLI is an advanced combination sensor sorting machine designed for precise separation of heavy metal fractions. By integrating four different sensors, including X-ray fluorescence (XRF), color recognition, 3D laser and inductive detection, this technology enables comprehensive analysis and sorting of materials based on their elemental composition and physical properties.

Key features and technical data

STEINERT KSS | XF CLI combines multiple sensor technologies to achieve in-depth material characterization.

The XRF sensor identifies elemental composition, making it possible to distinguish between metals such as zinc, copper and brass. The color sensor detects up to 16.8 million shades of color, while the 3D laser sensor analyzes the shape and size of the object. The inductive sensor detects metallic properties, ensuring precise differentiation between metal and non-metal objects.

How does the technology work?

Materials are fed into the machine where they are exposed to a series of sensors. XRF technology analyzes the elemental composition by exposing objects to X-rays and measuring the resulting fluorescence, enabling the identification of specific metals. At the same time, the color sensor detects surface nuances, the 3D laser sensor maps the geometry of the object, and the inductive sensor assesses metallic properties.

This data is combined to make precise sorting decisions, resulting in efficient separation of materials based on both chemical and physical characteristics.

Value creation

By combining multiple sensors in one unit, the machine can efficiently handle complex material flows and differentiate metals based on both chemical and physical properties. This in-depth analysis reduces the need for manual post-processing and minimizes material loss, both improving recovery rates and increasing financial gain.

The flexible configuration also makes it possible to customize the sorting process according to specific requirements, so the machine can be optimally integrated into existing facilities.

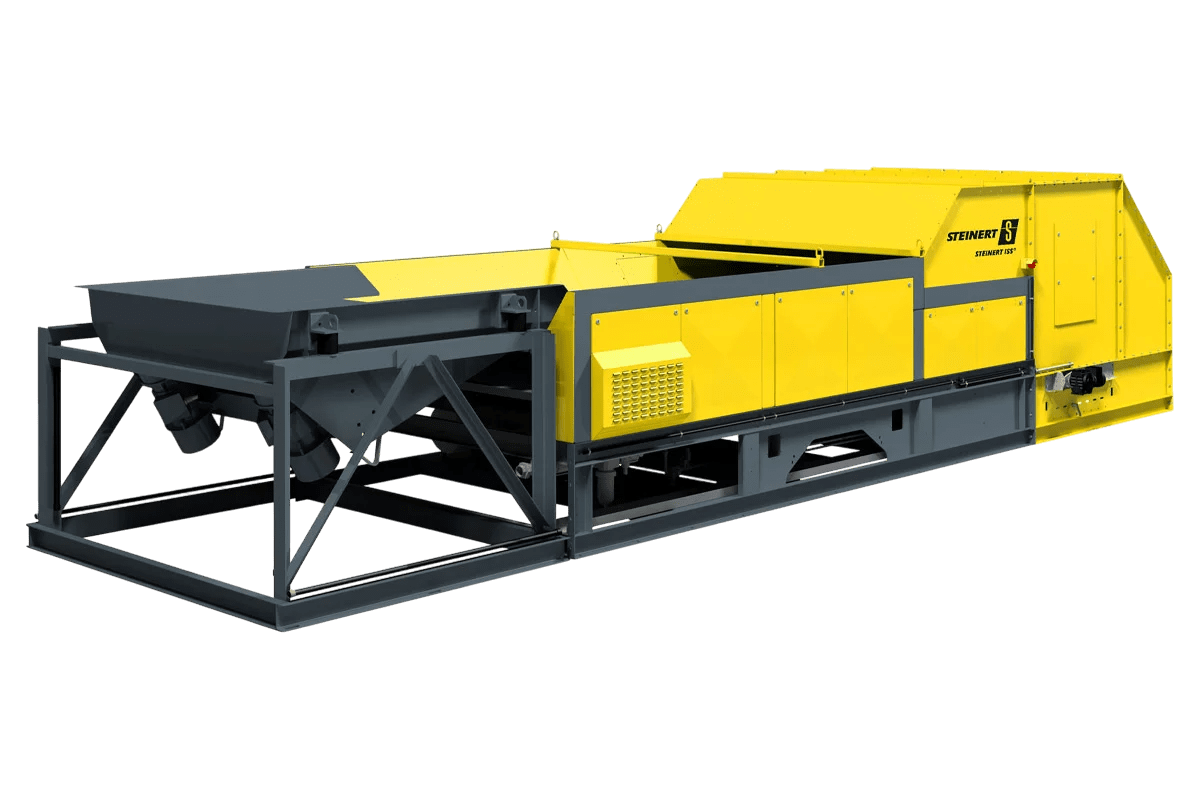

STEINERT ISS - Induction sorting

STEINERT ISS® is an induction sorting system designed to efficiently extract residual metals from material mixtures, especially stainless steel and composite materials such as cables and printed circuit boards.

Key features and technical data

The system is equipped with an inductive metal sensor located under the conveyor belt that generates an electromagnetic field. This field enables detection of conductive objects with a sensitivity of less than 1 mm. STEINERT ISS® is available in different working widths from 600 mm to 3,000 mm, making it suitable for a variety of applications.

How does the technology work?

The material is transported on an acceleration belt through the detection area where the inductive sensor detects conductive objects. When a metal object is detected, a precisely controlled air nozzle is activated, blowing the object out of the material stream. This process ensures efficient separation of metals from non-metallic materials.

Value creation

By integrating STEINERT ISS® into recycling processes, a higher purity of the recovered metals is achieved, increasing their market value. The system’s ability to detect and remove small metal particles improves the overall efficiency and profitability of the recycling process.

If your company is involved in recycling metals such as stainless steel or composite materials, STEINERT ISS® can optimize your sorting processes and improve the quality of the recycled materials.

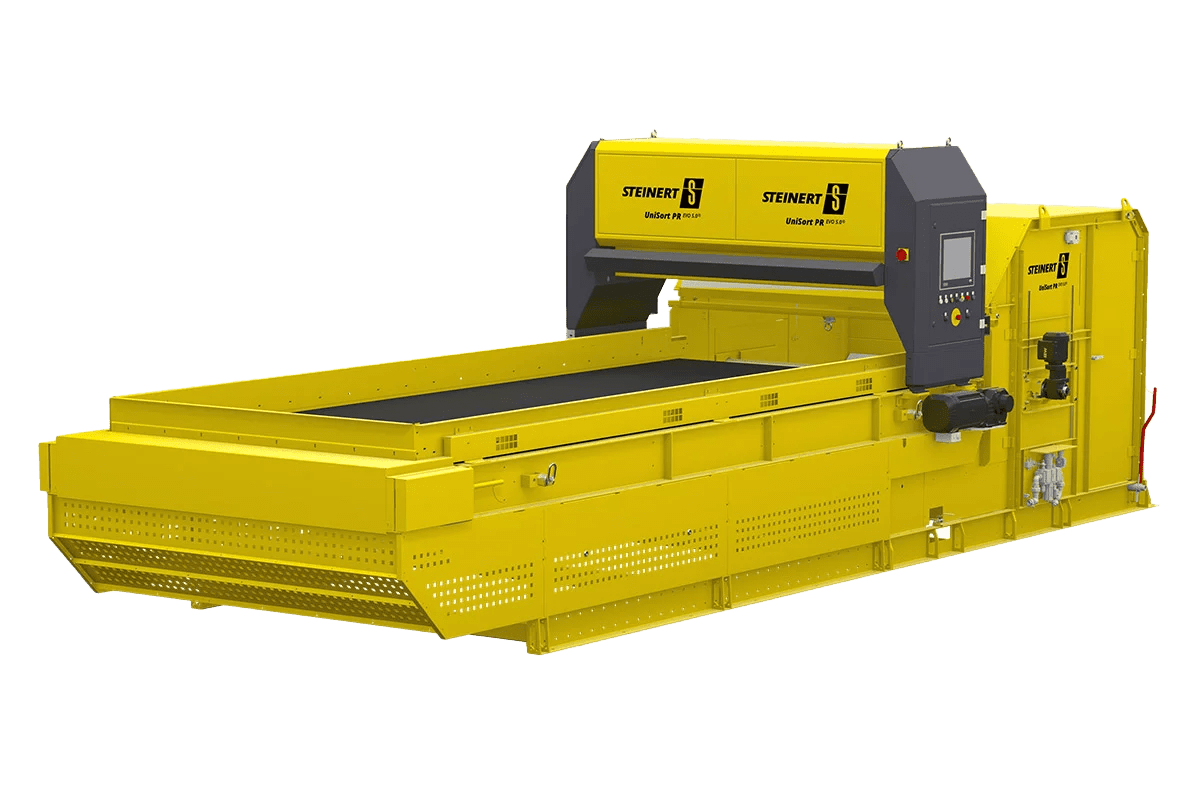

Steinert NIR - UniSort

UniSort PR EVO 5.0 is an advanced sorting solution from STEINERT, designed to optimize sorting results in waste management and recycling. This machine uses camera-based NIR technology with hyperspectral imaging (HSI) to achieve unprecedented visual and spatial resolution.

Key features and technical data

UniSort PR EVO 5.0 features several improvements including upgraded light boxes, improved valve manifolds, dynamic calibration, automatic white balance and advanced object recognition. These features ensure a more maintenance-friendly operation and deliver advanced sorting results.

Sorting of PET fractions: UniSort PR EVO 5.0 can differentiate between PET bottles and PET trays based on their chemical composition. This enables a pure PET bottle fraction, which facilitates subsequent processing and improves the purity of the recycled material.

Silicone cartridge handling: The machine is able to identify and remove silicone cartridges from the material stream. Although the outside of these cartridges is made of polyethylene (PE), residual silicone inside can contaminate recycled PE. UniSort PR EVO 5.0’s intelligent object recognition ensures that these contaminants are effectively removed.

General plastic sorting: In addition to the specific applications mentioned above, UniSort PR EVO 5.0 is suitable for traditional NIR applications in the sorting of plastics or plastic mixtures, sorting of substitute fuels, and in the green waste and wood waste sector.

How does the technology work?

The machine uses an HSI camera to analyze materials on the conveyor belt with high precision. The dynamic calibration continuously monitors the illumination spectrum without interrupting the sorting process, ensuring constant accuracy.

Upgraded light boxes improve long-term detection and simplify maintenance, while optimized valve blocks ensure precise separation of the waste stream.

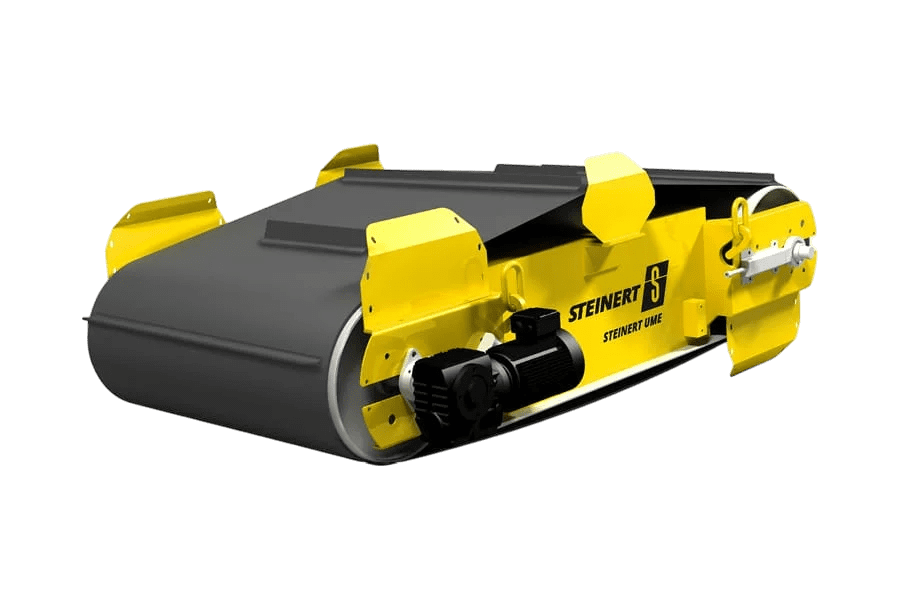

STEINERT UME - Universal Magnetic Separator

STEINERT UME is an electromagnetic overband magnet designed to effectively remove ferrous materials from various material flows. This technology is essential in the recycling and mining industry to ensure the purity of products and protect downstream machinery from damage caused by metal objects.

Key features and technical data

STEINERT UME is characterized by its powerful and deep magnetic field, which effectively captures ferrous parts even in deep material layers. This is achieved through the use of custom-made ANOFOL® coils made from anodized aluminum strip, resulting in a low weight-to-performance ratio and making oil-free design possible.

The magnet is available in working widths from 750 mm to 1,800 mm and can be supplied with either passive or active air cooling, depending on model and application.

How does the technology work?

When materials are transported on a conveyor belt, STEINERT UME is placed above the belt to extract ferrous materials from the material flow against gravity. Self-cleaning magnetic separators are equipped with a circulating conveyor belt with protrusions, which removes the attracted ferrous parts and drops them into a separate container. This process ensures continuous and efficient removal of unwanted metal objects from the material flow.

Value creation

The implementation of STEINERT UME in treatment processes brings significant benefits. The reliable removal of ferrous materials protects downstream machinery from damage, reducing maintenance costs and downtime. It also improves product quality by ensuring that the end products are free from unwanted metal contaminants, increasing their market value.

If you are looking for a reliable solution to remove ferrous materials from your material flow, STEINERT UME can improve the efficiency and quality of your treatment process.

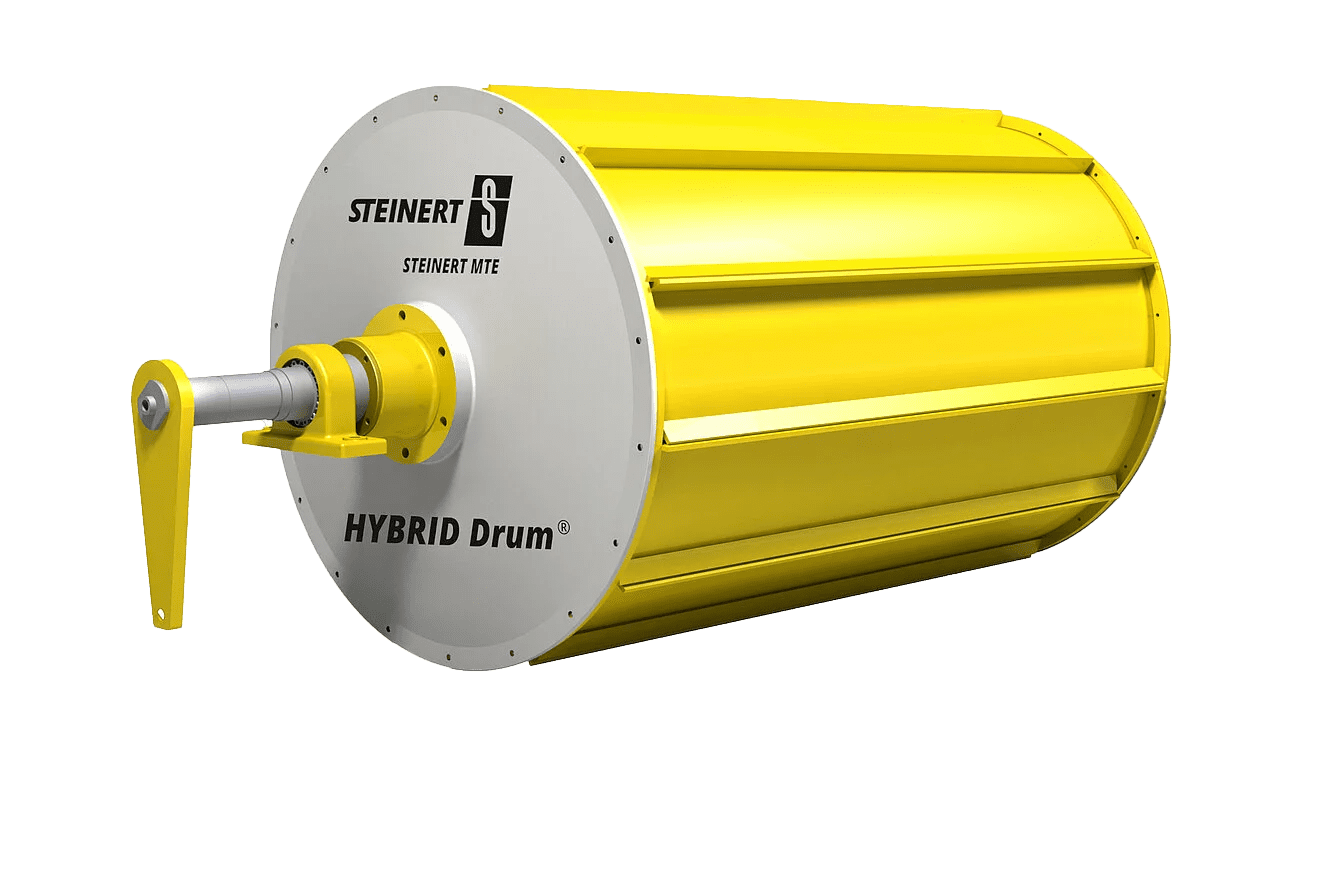

Steinert MTE - Drum magnet

The STEINERT MTE is an electromagnetic drum separator designed to efficiently separate ferrous materials from various bulk streams.

This technology is essential in the recycling and mining industry to ensure the purity of end products and protect downstream machinery from damage caused by metal objects.

Key features and technical data

The STEINERT MTE is equipped with an eccentric pole system that ensures optimal separation efficiency. The machine’s self-supporting frame design enables quick change of the conveyor belt in just 10 minutes, significantly reducing maintenance time.

In addition, the machine offers variable adjustment of the application point of the pole system, making it possible to adapt the separation to different material types and grain sizes. STEINERT MTE is available in different versions with working widths from 800 mm to 3,400 mm and diameters from 800 mm to 1,800 mm, making it suitable for a wide range of applications.

How does the technology work?

When materials are transported on a feed belt, STEINERT MTE is placed above the belt to extract ferrous materials from the material flow against gravity. Self-cleaning magnetic separators are equipped with a circulating conveyor belt with protrusions, which removes the attracted ferrous parts and drops them into a separate container.

This process ensures a continuous and efficient removal of unwanted metal objects from the material stream.

Value creation

The reliable removal of ferrous materials protects downstream machinery from damage, reducing maintenance costs and downtime. It also improves product quality by ensuring that the end products are free from unwanted metal contaminants, increasing their market value. The robust construction and efficient design of STEINERT MTE ensures a long service life and reliable operation in demanding conditions.