Fire

Spaleck

Spaleck is a German company with over 150 years of experience, known for providing cutting-edge solutions in vibration-based screening and separation. Their technology is used in a wide range of industries including recycling, mining and waste management. Spaleck’s machines ensure that materials such as metal, plastic and biomass can be sorted and separated with high precision, optimizing recycling processes and increasing yields.

At the heart of their success are their innovative 3D Combi screens and Flip-Flow systems, which efficiently screen materials without blockages or build-up, even in demanding environments. These technologies make it possible to achieve cleaner fractions and more uniform materials, reducing both machine wear and operating costs.

Spaleck’s flexible and modular solutions can be easily integrated into existing systems and customized to individual needs, making them a trusted partner for companies looking to improve their material handling and efficiency. Their machines also protect other equipment in the process by removing impurities early, extending the life of downstream sorting systems.

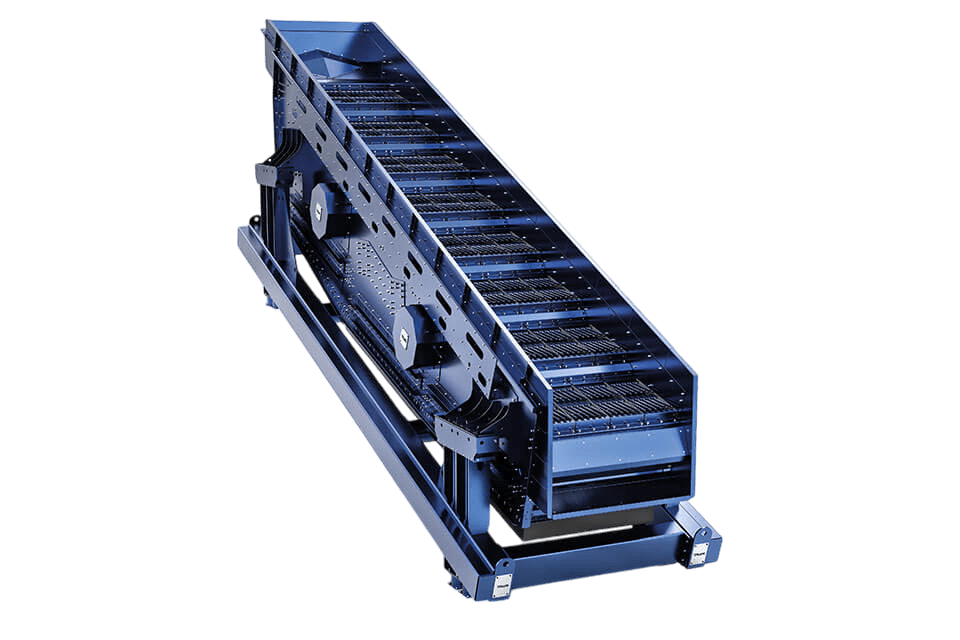

Flip-Flow sieve

SPALECK’s Flip-Flow screens are specially developed machines designed for efficient sorting of difficult, sticky or wet materials with separation cuts from 0.2 mm up to approximately 50 mm. These screens are ideal for handling materials that have traditionally been challenging to process with conventional screening technologies.

This technology is ideal for materials that normally clog standard sieves, such as wet waste or sticky substances.

Key features and technical data

- High performance: Flip-Flow sights ensure maximum aiming quality and reliability, even in demanding conditions.

- Flexibility: Adaptable to different material types and sizes, making them versatile in different industries.

- Efficiency: Reduces operational costs by optimizing the screening process and minimizing the need for maintenance.

Areas of application

Flip-Flow screens are suitable for a wide range of materials, including:

- Recycled materials

- Building materials

- Compost

- Waste wood

Their design makes them particularly effective for processing damp, wet or dry materials with inhomogeneous properties.

3D combination sight

SPALECK’s 3D Combi screener is an advanced solution designed for efficient sorting and recycling of different materials. This machine combines 3D technology in the upper deck with flip-flow technology in the lower deck, ensuring exceptional screening quality and maximum yield.

Key features and technical data

- 2-in-1 solution: Integrates two screening technologies into one compact unit, reducing the need for additional steel construction and saving space.

- High performance: Ensures consistently high screening results, even with difficult materials such as damp or sticky substances.

- Flexibility: Can handle a wide range of materials with separation cuts from approximately 0.2 to 120 mm.

Areas of application

The 3D Combi screener is ideal for classifying various recycled materials, including:

- Scrap metal

- Electronic waste

- Construction and demolition waste

- Household and commercial waste

- Compost

- Plastic fractions

- Biomass

This versatility makes it a valuable component of any recycling line looking to optimize their processes and output.

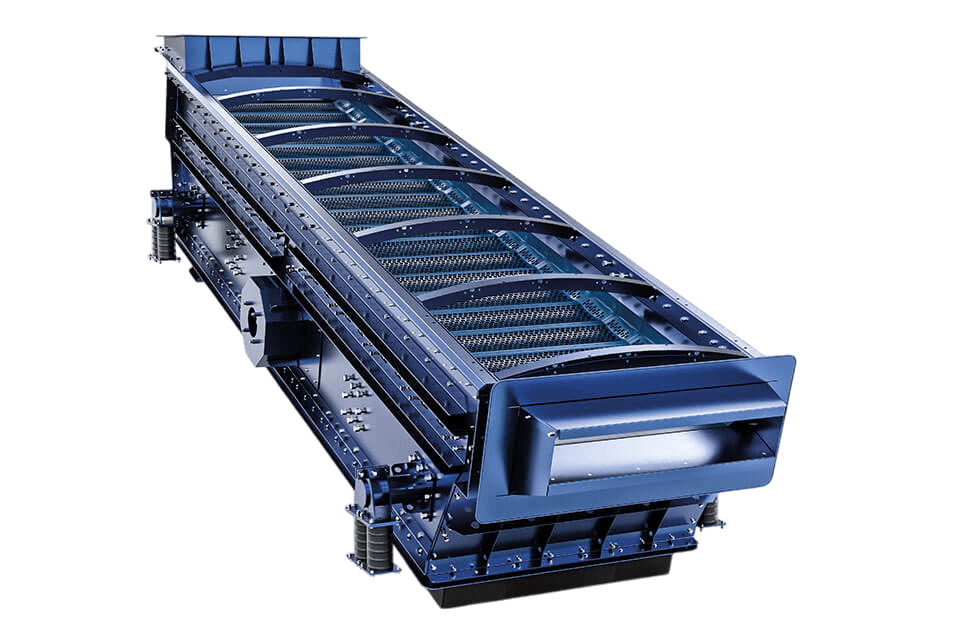

ActiveFEED infeed bunker

ActiveFEED is an intelligent infeed bunker that self-regulates the material feed to achieve predefined recycling targets.

It independently monitors the desired discharge rate and automatically adjusts the oscillation parameters to ensure a constant discharge rate, even with changing fill levels in the bunker. This prevents over- or underloading downstream sorting equipment and optimizes the overall efficiency of the recycling process.

Key features and technical data

SPALECK’s ActiveFEED feed bunker is an advanced solution designed to optimize the material supply in recycling lines. This self-regulating feed unit ensures a continuous and even supply of material to screening and sorting equipment, increasing the efficiency and yield of the recycling process.

Key features and benefits:

-

Self-regulating material supply: ActiveFEED automatically adjusts the material flow to maintain a constant and optimal supply for subsequent processes.

-

Improved sorting quality: By ensuring a consistent material feed, the precision of the sorting equipment is improved, resulting in higher purity of the final fractions.

-

Increased operational efficiency: The continuous and reliable material supply reduces downtime and increases the overall productivity of the recycling line.

The implementation of ActiveFEED in recycling plants has proven to set new standards in material input and sorting efficiency. For example, Swedish recycling company Stena has seen a significant improvement in their sensor-based sorting after integrating ActiveFEED, taking their sorting process to a new level.