Fire

Impact-Tec

They are known for providing robust and advanced machines including impact mills, hammer mills and shredders that are used in a variety of applications, from construction and electronic waste to glass and scrap metal.

Their technology is based on extensive experience in the design and optimization of slag mills and recycling plants. Prall-Tec machines are designed to handle some of the most demanding materials, such as concrete, steel, slag and other minerals. Their rotor technology is designed to ensure maximum reliability and efficiency even under constant load, making them ideal for separating metals from waste such as IBA (Incinerator Bottom Ash)IBA – Incinerator Bottom Ash – restmateriale fra forbrændingsanlæg. IBA indeholder metaller, sten og slagger, og kan sorteres for at udvinde genanvendelige metaller. More and concrete.

Prall-Tec’s PT series of impactors is one of the most versatile on the market, with a capacity of up to 220 tons of waste per hour. These mills are tailored to meet customer-specific needs, ensuring optimal performance in recycling metals, glass, and construction waste.

The company also offers efficient shredders that can be used for everything from automotive glass to metal waste, and can be customized with either two or four axles depending on the material.

Prall-tec machines ensure precise material separation and recycling while keeping operating costs low.

Mobile Impact Crusher (PT1.1)

Prall-Tec’s PT1.1 is a tracked mobile impact crusher designed to deliver maximum stability and performance in demanding recycling applications. It is particularly suitable for handling reinforced concrete, construction waste and other difficult materials, while maintaining a low operating weight and high flexibility.

Used for these materials

- Reinforced concrete

- Construction waste

- Difficult materials

Key features and technical data

The PT1.1 is equipped with fully hydraulic impactors with a 280 mm movement and Hardox wear plates at the outlet of the vibratory feed hopper. It is driven by a rotor with a power of 200 kW. The machine has a capacity of up to 150 tons per hour and a total weight of 32,000 kg. Its dimensions are 13,800 mm in length, 3,000 mm in width and 3,200 mm in height.

It produces an end product with a size of up to 45 mm.

How does the technology work?

The material is fed into the impact crusher via the vibrating feed hopper where it meets the hydraulic impactors.

These components work together to crush the material efficiently, resulting in a uniform and controlled fragmentation that is ideal for further processing.

Value creation

By integrating the PT1.1 into the recycling process, companies gain a reliable and efficient solution for handling demanding materials. Its robust design and advanced features ensure high performance, while its mobile design provides the flexibility to operate at different work sites.

This leads to increased productivity and reduced operating costs.

Prall-Tec’s PT1.1 represents an advanced mobile impact crushing solution that combines robustness, efficiency and flexibility.

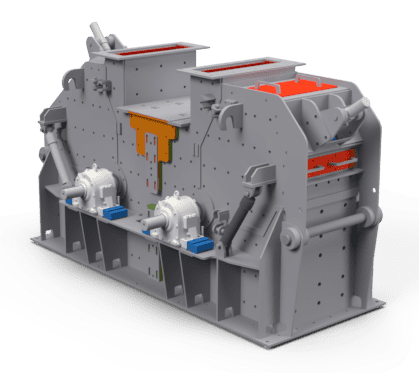

Balling Mill (PTV)

Prall-Tec’s PTV series of balling mills are designed for efficient processing and shaping of pre-treated materials with metal content. These machines enable the separation of metals from composite materials, resulting in clean fractions ready for further processing.

Key features and technical data

The PTV series is suitable for processing a range of materials, including:

- Automotive Shredder Residues (ASR)

- Cable bridge

- Treatment of non-ferrous mixed scrap

- Electronic waste (WEEE)

- Other metal containing materials

How does the technology work?

Material is fed into the machine via a feed channel or conveyor belt located centrally above the rotor. Larger pieces that do not pass through the pre-set gap between the hammer and anvil are crushed first. Then the composite material is further separated by impact and friction via the balling bar and the processed product is discharged through an installed grid basket in the desired size.

If the desired size or separation is not achieved, repeat the process until the material is sufficiently broken down.

Lighter materials such as dust or fluff can then be removed using air separation based on specific gravity, resulting in a clean heavy fraction that can be easily separated from aluminum and other materials.

These machines are designed to deliver high performance and reliability in demanding recycling and processing environments.

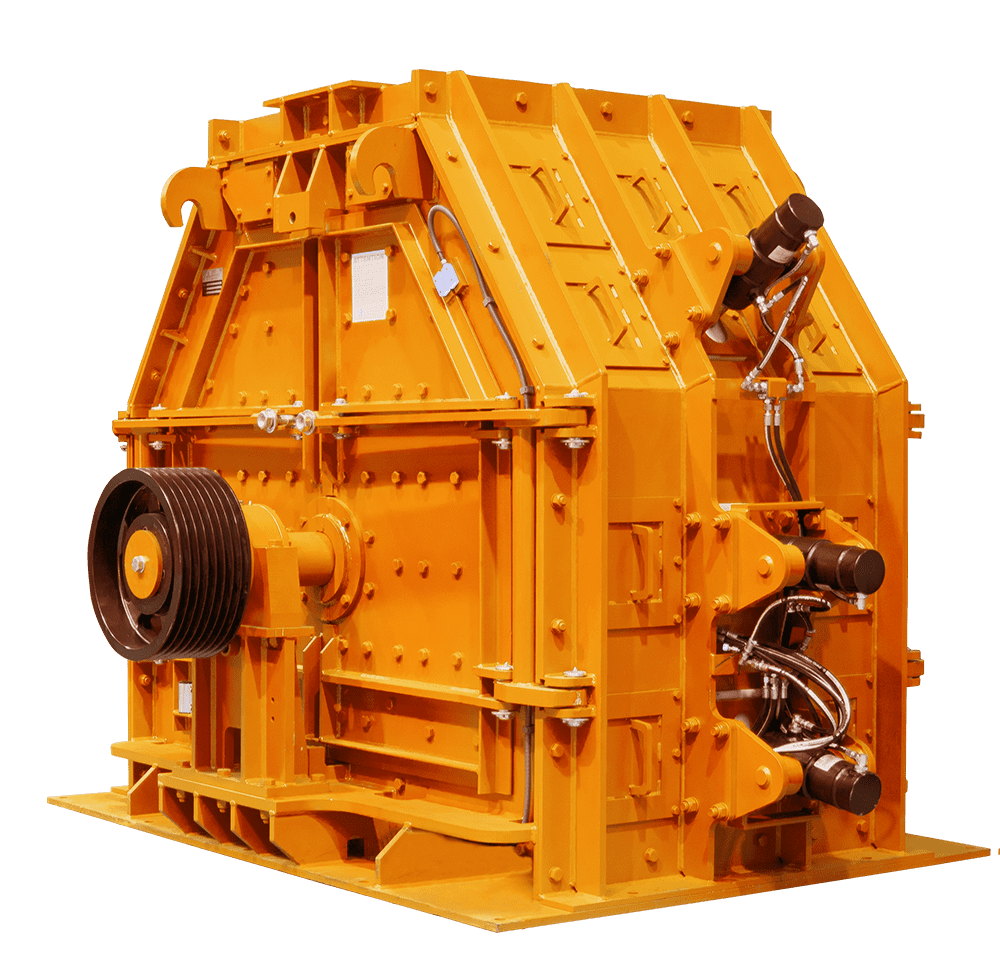

Impact Crushers (PT)

Prall-Tec’s impact mills are designed to process hard materials such as concrete, stone, metals and slag. These machines utilize a powerful rotor that rotates at high speed and throws the material against impact plates that crush it into smaller pieces. By using precisely adjustable impact angles and rotor systems, an optimized breakdown is achieved, crushing the material to the desired size.

The impact mills are highly efficient at liberating metals from composite materials and can be adapted to different granulations, making them versatile in waste recycling processes.

Key features and technical data

High crushing capacity and lower operating costs: The design ensures efficient processing of materials with reduced costs.

Powerful rotors and robust strike plates: Ensure reliable operation even in the toughest conditions.

Maintenance-friendly design: Provides quick access to maintenance devices, minimizing downtime.

Optimal customization: Tailor-made solutions for specific materials and applications.

Areas of application

PT Series impact crushers are versatile and can be used for a variety of materials, including:

- Construction waste

- Concrete

- Asphalt

- Natural stone

- Slag and metals

- Electronic waste (WEEE)

- Batteries

This flexibility makes them ideal for both recycling applications and raw material processing.

The PT series includes several models with different capacities and dimensions. For example, the PT 110/100 model has an inlet size of 770 x 1020 mm, a weight of 8700 kg and can handle a throughput of up to 200 tons per hour. It is equipped with a 200 kW direct drive motor and can process materials up to 700 mm in size.

Fine Grinding Mill (PTRF)

Prall-Tec’s PTRF series of fine grinding mills are designed for precise and efficient grinding of mineral products, enabling optimal separation of organic materials in subsequent processes. These mills are equipped with either one or two rotors, depending on the application, and can handle input materials up to 30 mm in size.

A unique feature of the PTRF series is that the machine avoids crushing organic materials, facilitating efficient separation downstream. By adjusting the speed, specific grain curves and measured grain sizes can be achieved.

Key features and technical data

Optimal material degradation: Efficient separation of minerals and foreign substances.

Limited crushing of impurities and organic materials: This enables easy separation in subsequent processes.

Reduced energy consumption per ton: Compared to conventional machines, the PTRF series requires less energy for grinding.

Tailor-made wear parts: Components are specifically selected for the application, extending lifetime and reducing maintenance costs.

Areas of application

PTRF fine grinding mills are versatile and can be used for a variety of materials and industries, including:

- Glass processing: Efficient processing of container and hollow glass.

- Laminated glass preparation: Ensures optimal separation of glass layers.

- Machining aluminum and non-ferrous metals: Enables precise preparation for further separation.

Shredder (PTG)

Prall-Tec’s PTG Shredders are powerful shredders that use either two or four axles to process different types of waste, including glass, metals and automotive waste.

Shredders work by tearing and cutting the material into smaller pieces using slowly rotating shafts equipped with powerful blades. The low rotational speed minimizes wear and energy consumption, while enabling the processing of high-density materials or complicated structures, such as laminated glass or automotive scrap.

The four shafts ensure a uniform breakdown, especially when it comes to composite materials or materials with complex bonds such as glass with foil layers.

Key features and technical data

PTG shredders are versatile and can be adapted to different materials and applications. While the 4-axis model is ideal for handling thicker and more complex glass panes, such as bulletproof glass up to 80 mm thick, the 2-axis model is often sufficient for simpler materials.

Both models ensure a smooth and continuous material feed and can function as feed units with different bunker configurations.

One of the main advantages of the PTG series is its low operating costs. The slow rotation speed of the shafts reduces wear, even when processing glass with strong PVB films, which also contributes to quiet operation. This design ensures a cost-effective and reliable solution for glass recycling.

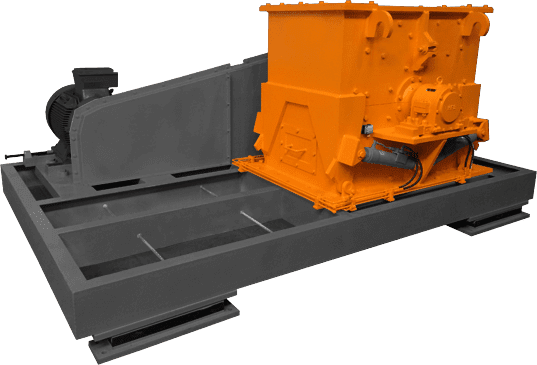

Hammermill (PTH)

The hammer mill housing is constructed in an advanced welded structure with two hinged parts that can be opened hydraulically. Inside, exposed areas are reinforced with wear-resistant Hardox plates or castings and the rotor disks are made from materials suitable for hammer mills.

The drive system consists of a motor pulley and a mill pulley that can be equipped with different power levels. Depending on the drive power, which ranges from 7.5 kW to 300 kW, the hammer mills can achieve a throughput of up to 60 tons per hour and have a dead weight between 2 and 6 tons.

Key features and technical data

Flexible material processing: Can process a wide range of materials, making them versatile in different industries.

Low maintenance: Designed with a focus on minimizing operating and maintenance costs.

Hydraulic opening: Enables easy removal of foreign objects and simplifies maintenance.

Robust construction: Ensures long life and reliable operation even in demanding conditions.

Areas of application

PTH series hammer mills are ideal when a final grit size of 1 mm or less is required. In addition to grinding limestone, phosphates and gypsum, they are also effective for glass recycling and other applications where fine grinding is needed.

Depending on model and configuration, PTH hammer mills can be customized to specific needs in terms of feed size, material and desired final grain size. Prall-Tec offers advice and support based on over 25 years of experience in hammer mill technology to ensure the optimal solution for each customer’s requirements.