Husmann is a partner in the development of innovative and efficient waste management solutions. With over 40 years of experience, Husmann has built a strong reputation for technological advancements and durable machines used throughout Europe. The company specializes in machines for shredding, sorting and recycling different types of waste materials. Their products are engineered with a focus on robustness, energy efficiency and flexibility, making them the preferred choice for many industries that require reliable waste treatment.

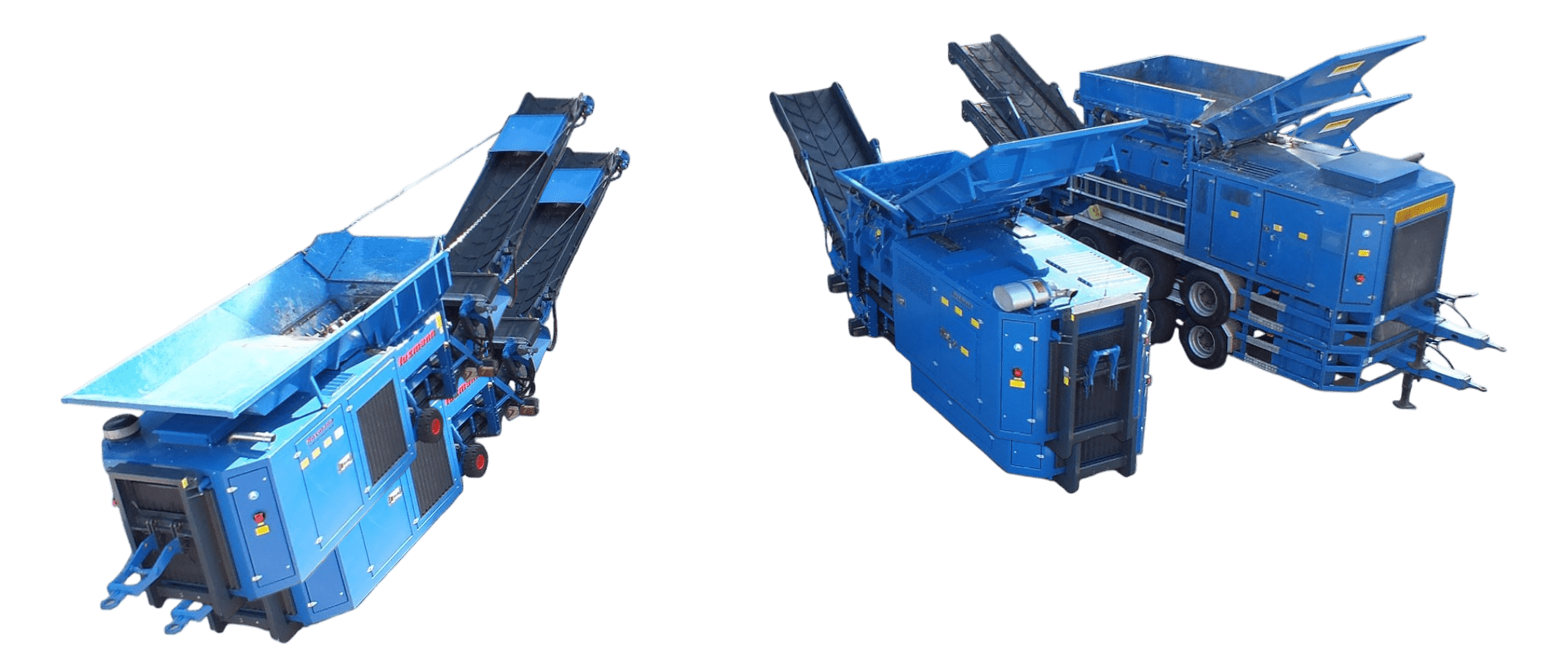

Husmann machines are known for their technological complexity and their ability to be adapted to different applications. Their shredders and compactors are available as both mobile and stationary solutions, allowing customers to choose the most suitable solution for their specific needs.

A key component of Husmann machines is their hydraulic systems, which ensure maximum performance and reliability. In addition, their machines use advanced sensors and control systems that monitor operations in real-time, improving efficiency and reducing the risk of downtime.

Shredder

Husmann shredders are designed to shred materials such as waste wood, plastic, construction waste and green waste. They use a two-shaft shredding technology that ensures precise and controlled shredding with minimal energy consumption.

HL II Series: This series of two-axle shredders is built for demanding applications. The machines work by slowly rotating shafts that pull the material in and cut it into smaller pieces, making them ideal for both wood waste and mixed construction waste. The HL II series is available as both stationary and mobile devices, providing flexibility for different workplaces

Hydraulic system: The shredders are equipped with advanced hydraulic systems that allow the operator to adjust speed and cutting force based on material type and density. This provides better control and efficiency during the breakdown process.

Overload protection: Husmann shredders are designed with an automatic reversing system that protects the machine from overloads and prevents blockages, extending machine life and reducing downtime.

Slowly rotating shafts: Provides smooth and controlled shredding of materials, ensuring low energy consumption and minimal wear on the machine. The slow pace reduces the risk of overheating and allows for continuous operation.

Mobility: The HL series offers both stationary and mobile models, so they can be used at both fixed sites and in different workplaces. The mobile units offer great flexibility when you need to move machines between different locations