Fire

Forrec

Their machines are designed to break down a wide range of materials such as plastic, metal, rubber and electronics into smaller fractions, making them ideal for recycling processes. Forrec’s product line includes powerful primary and secondary shredding systems that can handle large volumes of waste and turn them into recyclable materials.

The company is known for its robust and reliable solutions, where advanced technology ensures optimal performance and energy efficiency. Their machines are designed to be durable and easy to maintain, making them a natural choice for businesses looking for reliable waste management solutions.

At Viggo Bendz, we offer both standalone Forrec machines and complete solutions where we combine Forrec’s shredding systems with other specialized technologies.

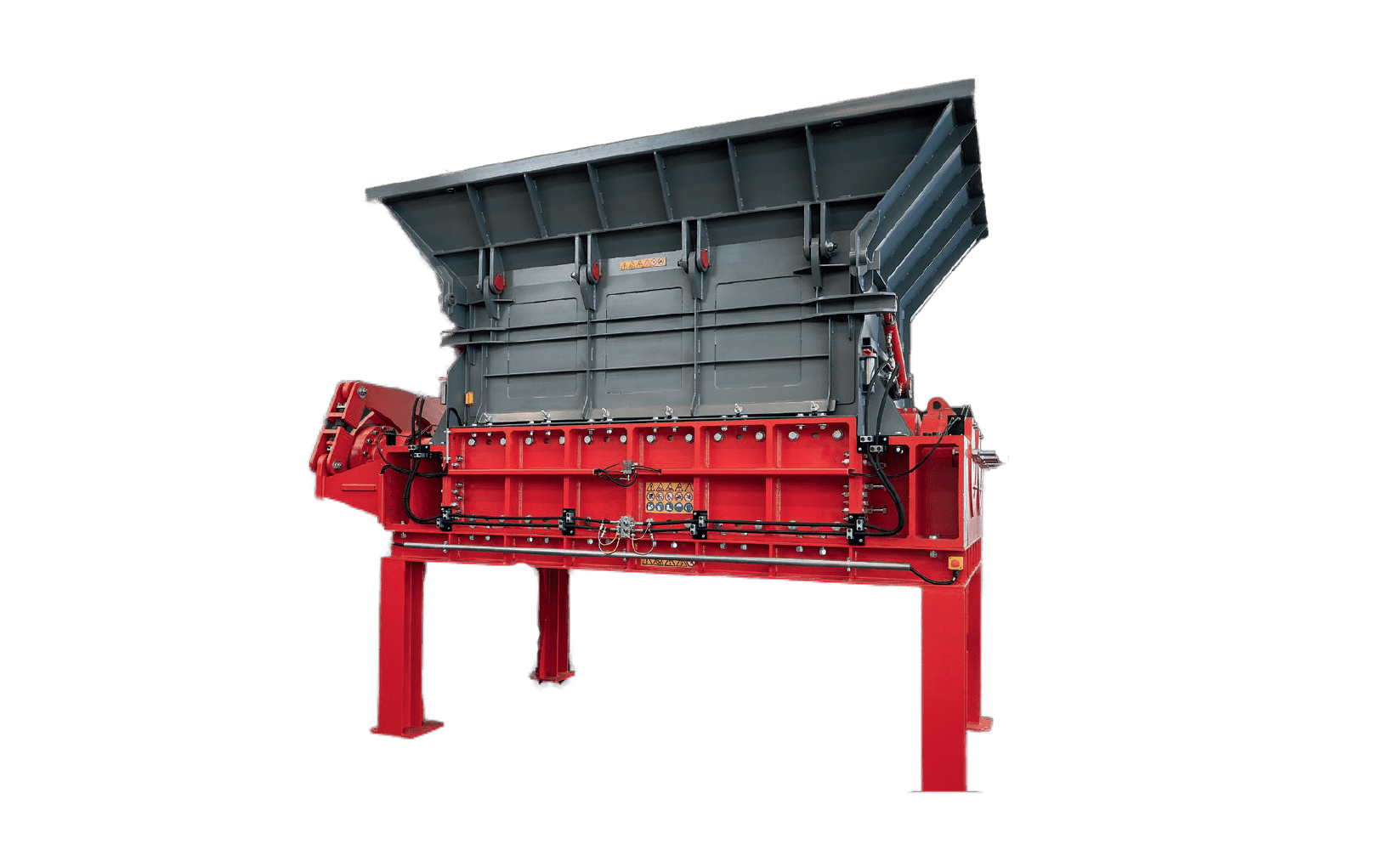

TQ Shredder (4-axle)

FORREC’s TQ series four-shaft shredders are designed for intensive solid waste processing where high demands are placed on strength, reliability and precise control over the size of the outgoing material. These machines are designed to optimize operating costs and minimize maintenance needs, making them ideal for demanding waste processing applications.

Used for these materials

- Refrigerators

- Electronic waste (WEEE)

- Plastic

- Electrical cables and motors

- Wood

Key features and technical data

TQ Series shredders are characterized by a robust steel structure that ensures machine durability in demanding operating conditions. The external bearings protect against material contamination and extend the lifetime of the moving parts. The blades are made of special steel, which guarantees high cutting efficiency and resistance to wear.

In addition, the machines are equipped with an automatic lubrication system that reduces the need for manual maintenance and ensures constant optimal performance.

How does the technology work?

The four shafts of the TQ series shredders work together to ensure an efficient and consistent shredding process. The material is fed into the machine where it is gripped by the rotating shafts and broken down to the desired size. The use of sorting grids ensures that only material of the correct size passes through, resulting in a homogeneous end product.

Value creation

Efficient shredding is the foundation of any successful recycling process. The subsequent sorting and separation processes typically have a size limit on the material they can handle, making reliable and accurate shredding a necessary first step in any sorting line.

A TQ shredder ensures that the material achieves the right size and uniformity, maximizing efficiency in the next step of the process.

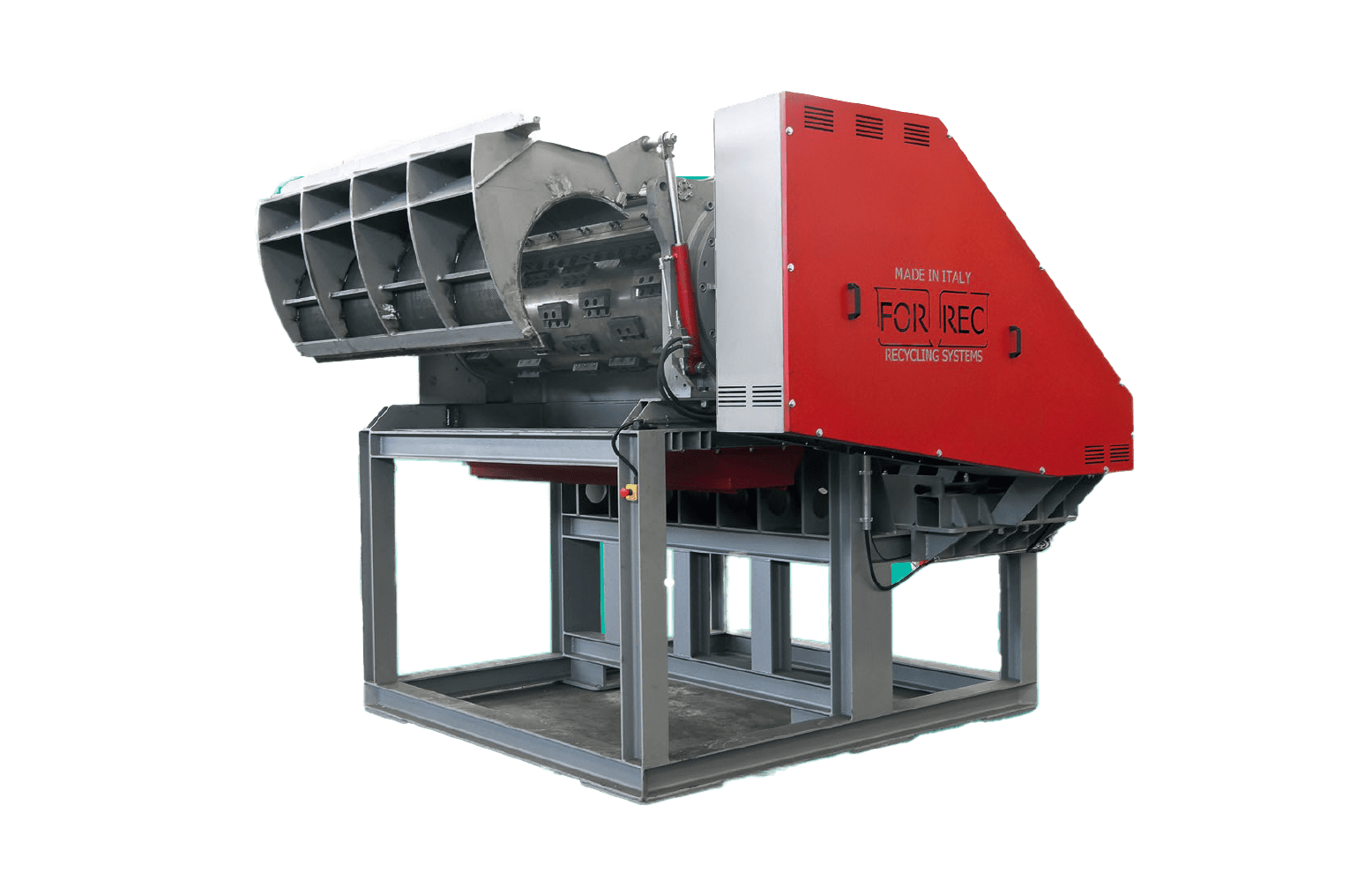

FR Shredder (2-axle)

FORREC’s FR series of double-shaft shredders with specialized blades are designed to efficiently process municipal solid waste, bulky waste, industrial waste, baled and loose materials. These machines are designed to handle large volumes of material with high reliability and reduced maintenance costs.

Used for these materials

- Municipal solid waste

- Bulky waste

- Industrial waste

- Baled materials

- Loose materials

Key features and technical data

FR Series shredders are equipped with specialized blades made from wear-resistant steel, ensuring long lifetime and efficient cutting. The bearings are located outside the cutting chamber to protect them from waste materials and the machine’s steel construction contributes to its robustness.

The axles are removable for easy maintenance and the hydraulic transmission ensures stable and powerful operation. PLC-controlled shaft rotation enables the processing of large amounts of material without the need for additional equipment.

How does the technology work?

The material is fed into the shredder hopper where the two shafts with special blades rotate and cut the material into smaller pieces. The PLC-controlled rotation cycle ensures a continuous and efficient cutting process, even with large amounts of material, preventing machine stops due to overload or blockages.

Value creation

By integrating the FR Series double-shaft shredders into waste management processes, an efficient reduction of waste volume is achieved, facilitating subsequent handling and processing.

The robust construction and durable components ensure reliable operation with minimal maintenance needs, reducing operating costs and increasing overall plant efficiency.

FORREC’s FR series of double-shaft shredders with specialized blades represent a reliable and efficient solution for processing different types of waste. Their advanced design and technical features ensure optimal performance, making them a valuable investment for waste management and recycling companies.

AE Down splitter (1-axle)

FORREC’s AE series of compact single shaft splitters are designed for efficient pre-processing of materials such as electronic circuit boards, electrical cables and plastics. These machines deliver precise granulation and prepare the material for subsequent processes, making them ideal for companies looking for a reliable and versatile shredding solution.

Used for these materials

- Lightweight plastic

- Wood

- Paper and cardboard

- Electrical cables

- Electronic circuit boards

Key features and technical data

The AE Series shredders combine the technology of larger single shaft machines with a compact and robust design. They are equipped with easily interchangeable cutting plates and an adjustable sorting grid that enables the production of material in the desired size. A hydraulic feeder ensures smooth material feeding, while the special steel shaft guarantees durability and efficiency. The compact design of the machines makes them both economical and easy to maintain.

How does the technology work?

The material is fed into the shredder where the hydraulic feeder presses it against the rotating shaft. The interchangeable cutting plates reduce the material to the desired size, determined by the mounted sorting grid. This process ensures uniform granulation, which is essential for the effectiveness of subsequent processing stages.

Value creation

Implementing an AE Series shredder in the production line enables precise control over material size, which is crucial for the efficiency of downstream processes such as sorting, separation and recycling. The uniform granulation improves the quality of the final product and optimizes operational costs by reducing the need for additional processing.

FMS Granulator

FORREC’s FMS series of granulators are designed for fine grinding of components from plastic molding, injection and blow molding, extrusion (pipes, profiles, plastic sheets), loose and rolled film and blocks. These machines are designed to handle demanding materials with maximum efficiency.

- Tires

- Plastic

- Electrical cables

- Refrigerators

- Pneumatic cables

Key features and technical data

FMS granulators are constructed with special steel components, making them ideal for processing even the most challenging materials. The unique cutting system ensures energy savings and a significant reduction of dust during waste treatment. The machines are equipped with automatic lubrication, special steel blades, a robust steel construction, interchangeable sorting grids and hydraulic openings.

How does the technology work?

The material is fed into the granulator where it meets the rotating knives made of special steel. These blades efficiently cut the material down to the desired size, which is determined by the interchangeable sorting grid.

The robust steel construction and automatic lubrication system ensure stable and continuous operation, while the hydraulic opening system facilitates maintenance.

Value creation

By integrating the FMS granulator into the processing line, a uniform and precise granulation of materials is achieved, improving efficiency in subsequent processes such as sorting and recycling.

FORREC’s FMS series of granulators represents a reliable and efficient solution for fine grinding a wide range of materials.

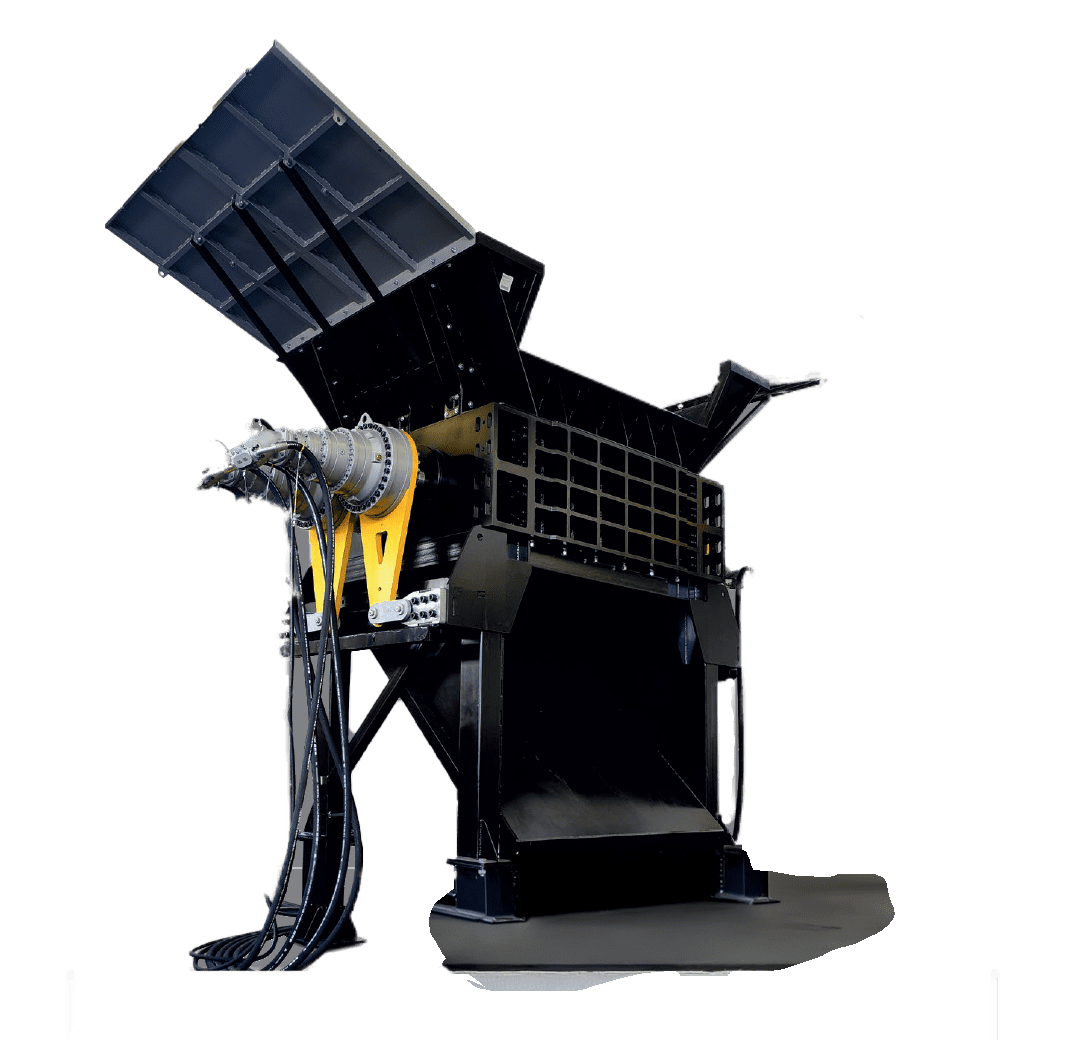

Hammer mills

FORREC’s hammer mills, including the Z14, Z15 and Z16 models, are designed to provide robust and efficient treatment of metal and WEEE waste. These machines are ideal for processing hard materials such as aluminum, iron, motors and electronic waste, enabling efficient reduction of metal materials.

Used for these materials

- Aluminum

- Iron

- Electric motors

- Electronic waste (WEEE)

Key features and technical data

Hammer mills are characterized by a robust structure and high performance. The hydraulic opening mechanism in the upper part of the machine allows quick access to wear parts, making maintenance easier. Hammers can be customized in type, thickness and quantity to meet specific processing needs. In addition, the machines are equipped with special vibration dampers located on the machine support structure to reduce stress.

How does the technology work?

The material is fed into the hammer mill where rotating hammers crush it into smaller fragments. The robust construction and customized hammer configuration ensures an efficient crushing process resulting in a homogeneous output size, which is essential for subsequent recycling processes.

Value creation

The integration of FORREC’s hammer mills into waste treatment processes enables a significant reduction in material size, facilitating handling and transportation.

The efficient crushing improves the quality of the recovered material, increasing its value and usability in subsequent recycling processes.

The machines’ durable design and easy maintenance also ensure a long lifetime and reduced operating costs, contributing to sustainable and cost-effective operations.

FX Shredder (Rotary Shear)

FORREC’s FX series of rotary cutting machines are designed for efficient processing of scrap metal, including pressed or whole cars and general scrap metal. These twin-shaft shredders are designed to handle demanding materials with high performance and reliability.

Used for these materials

- Light scrap metal

- Cars

- Pressed cars

- Rollers

- Sheet iron

- Different scrap iron from different processes

- Bulky waste

Key features and technical data

FX Series shredders are equipped with a configuration of four motors, two for each shaft, ensuring powerful operation. The replaceable special steel blades and robust construction guarantee excellent working standards with reduced maintenance times. The low rotation speed enables the development of very high torques, designed to process even the most difficult materials.

Hourly production ranges from 15 to 40 tons, guaranteeing unprecedented levels of productivity.

How does the technology work?

The material is fed into the shredder where the two shafts with specially designed blades rotate at low speed but high torque, effectively cutting and shredding the material. This process ensures an efficient reduction of material size, which is essential for subsequent recycling processes.

Value creation

Efficient processing of scrap metal requires a powerful and reliable shredder that can handle large and complex materials without compromising on reliability. FX series rotary cutters ensure a uniform and controlled reduction of the material, making it easier to handle and transport.

By delivering a precisely cut output, the machine ensures that the shredded metal can be integrated directly into subsequent sorting and recycling processes without the need for further treatment. The high production capacity and low maintenance requirements make it possible to maximize uptime and minimize costs.

With a thoughtful design that combines low speed and high torque, the shredder prevents unnecessary wear and energy waste, providing an economical and sustainable solution. For companies working with scrap metal and bulky waste, the FX series is a crucial step towards a more efficient and profitable recycling process.