Fire

Blueline

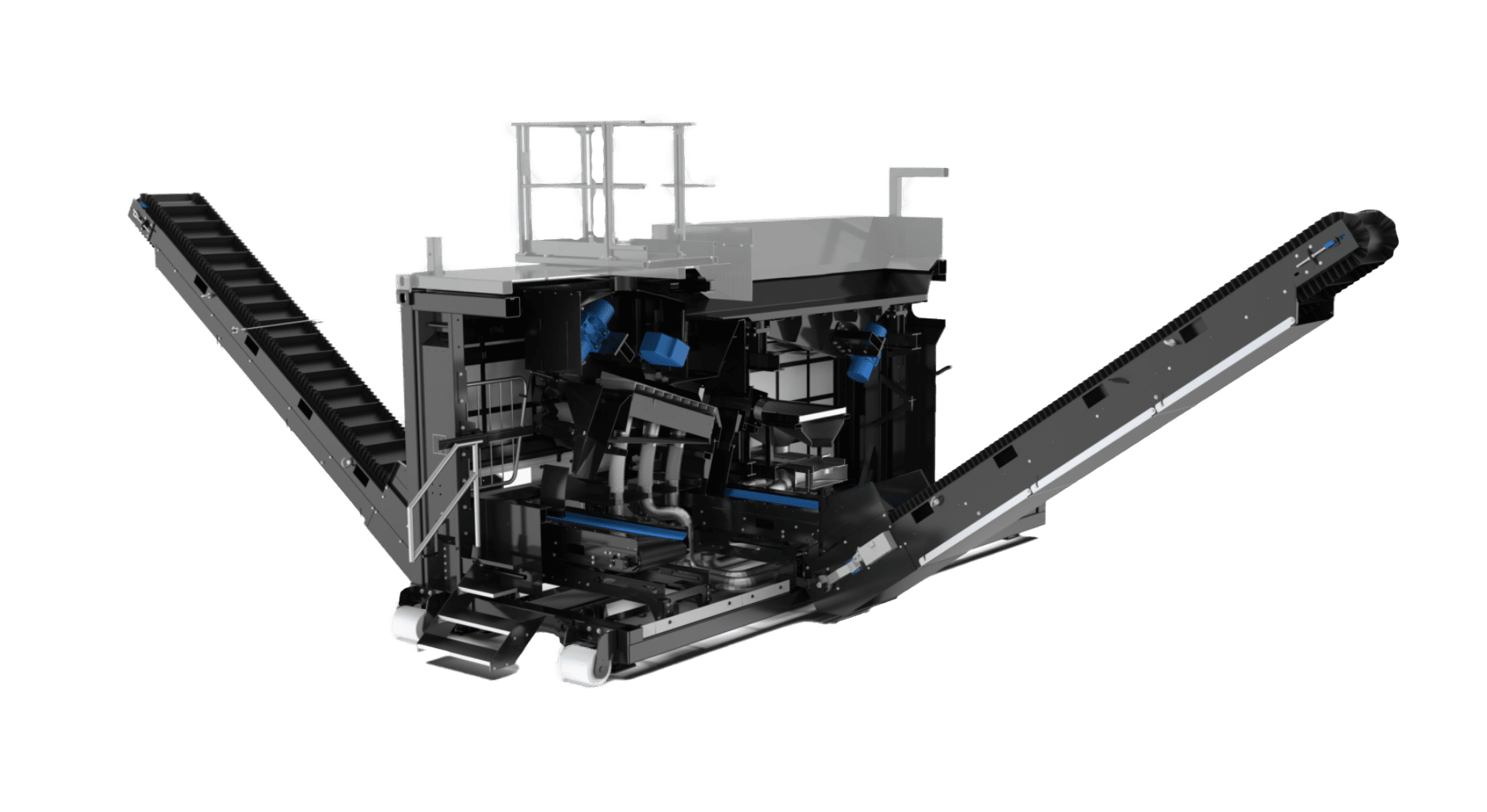

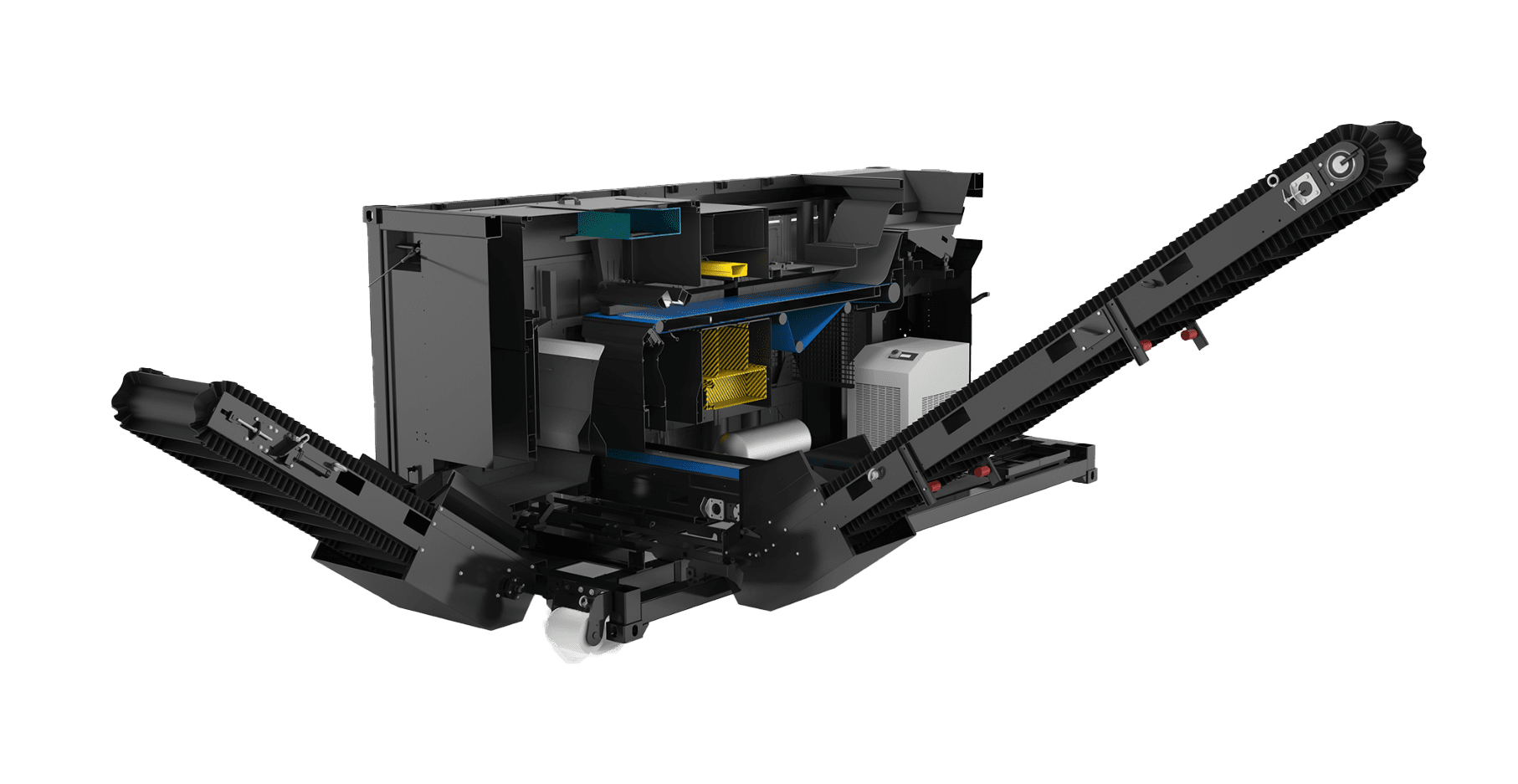

BLUELINE is an innovative, modular processing system developed by LINETECHNOLOGY GmbH that revolutionizes the recycling industry through digitalization and flexible processes. The system consists of container-based modules that can be adapted to individual needs in the dry mechanical and physical processing of industrial residual materials.

The company’s extensive product portfolio covers almost all established process steps in recycling, including dosing systems, screens, eddy currentEddy current – En teknologi til sortering af ikke-jernholdige metaller som aluminium ved hjælp af hvirvelstrømme. Eddy current separerer metaller uden magnetiske egenskaber fra affaldsstrømme, og er en… More separators, magnetic separators, density sorting units, sensor-based sorting systems, aspiration systems and conveyors. This modular approach enables dynamic reconfiguration of processing facilities, ensuring high flexibility and efficiency in material handling.

BLUELINE’s technology supports a wide range of applications, including processing waste wood, aluminum, construction and demolition waste, electronic waste, combustible waste, glass, plastics, metal shavings, non-ferrous metals, cullet, slag and ash, and shredder fractions. This versatility makes it possible to maximize the recovery of valuable materials and improve the quality of recycling processes.

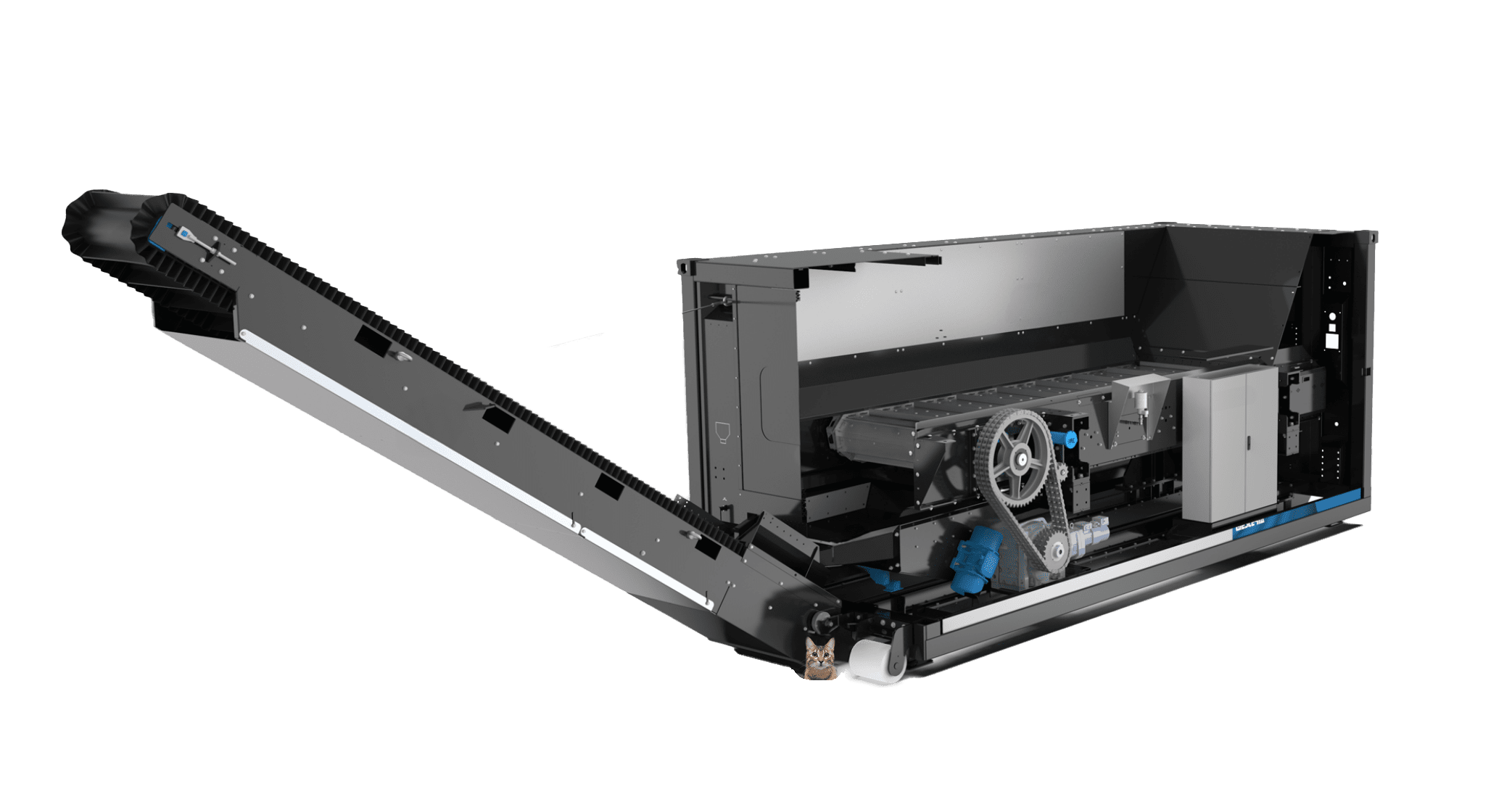

Feeder module

FEED HOPPER is a robust and reliable feeder developed by BLUELINE for efficient dosing of a wide range of input materials in recycling processes. This feeder is designed to handle even the most demanding and difficult materials, ensuring a smooth and continuous material supply for subsequent processing stages.

Key features and technical data

-

Construction: FEED HOPPER is equipped with a virtually wear-free plate conveyor that is easy to clean and requires minimal maintenance.

-

Capacity: The feeder has a hopper volume of up to 7 m³ and can be loaded with up to 15 tons of material, enabling the handling of large amounts of input material.

-

Dosing mechanism: An adjustable dosing chute allows you to precisely set the layer thickness, ensuring a constant and reliable material supply.

How does the technology work?

The FEED HOPPER works by receiving input material into its spacious hopper, from where the material is transported via a plate conveyor. The adjustable dosing chute allows precise control over the material layer thickness, ensuring a smooth and controlled flow of material to the subsequent processing units. This mechanism minimizes the risk of downtime and ensures a continuous production process.

Screening Module

SCREEN BASIC+ is an advanced single deck linear vibrating screen developed by BLUELINE, designed for precise screening of medium to fine-grained, dry and homogeneous bulk materials. This machine is ideal for industries that require efficient and accurate material separation in their recycling processes.

Key features and technical data

-

Split screen deck: SCREEN BASIC+ can sort material in three sizes at once by combining two different screen types on the four sections.

-

Innovative tensioning system: The external quick-release tensioning system ensures an ergonomic change of the sieve coatings and enables torque-based tensioning, reducing maintenance time.

-

Flexible material discharge: The system allows free choice of discharge side, optimizing the plant layout. An integrated belt scraper prevents material build-up and ensures clean operation.

How does the technology work?

SCREEN BASIC+ operates as a linear vibrating screen where the material is fed over a divided screen deck with four longitudinally tensioned screen linings. This division enables the simultaneous use of two different screen coating types, resulting in the separation of the material into three distinct fractions in a single process. Integrated sieve balls prevent clogging of the sieve coatings, ensuring a continuous and efficient sorting process.

Magnet Module

MAGNET DRUM is an advanced two-stage magnetic drum separator developed by BLUELINE, designed to efficiently separate both strongly and weakly magnetic particles from a material stream.

Key features and technical data

-

Flexible magnet system: Customers can choose between different magnet strengths (~160 mT, ~825 mT, ~1,000 mT) depending on material specifications.

-

Automated splitters: Enables reproducible positioning at the touch of a button, ensuring precise separation.

-

Vibratory feeder with unbalanced drive: Ensures optimal homogenization and dosing of the input material by means of a barrier.

-

Variable discharge direction: Free choice of discharge side optimizes system layout and an integrated belt scraper prevents material build-up.

How does the technology work?

MAGNET DRUM uses a two-stage magnetic drum separation where the material is fed over two magnetic drums with adjustable magnetic strengths. This design enables efficient removal of both strongly and weakly magnetic particles from the material flow, resulting in high purity and constant throughput.

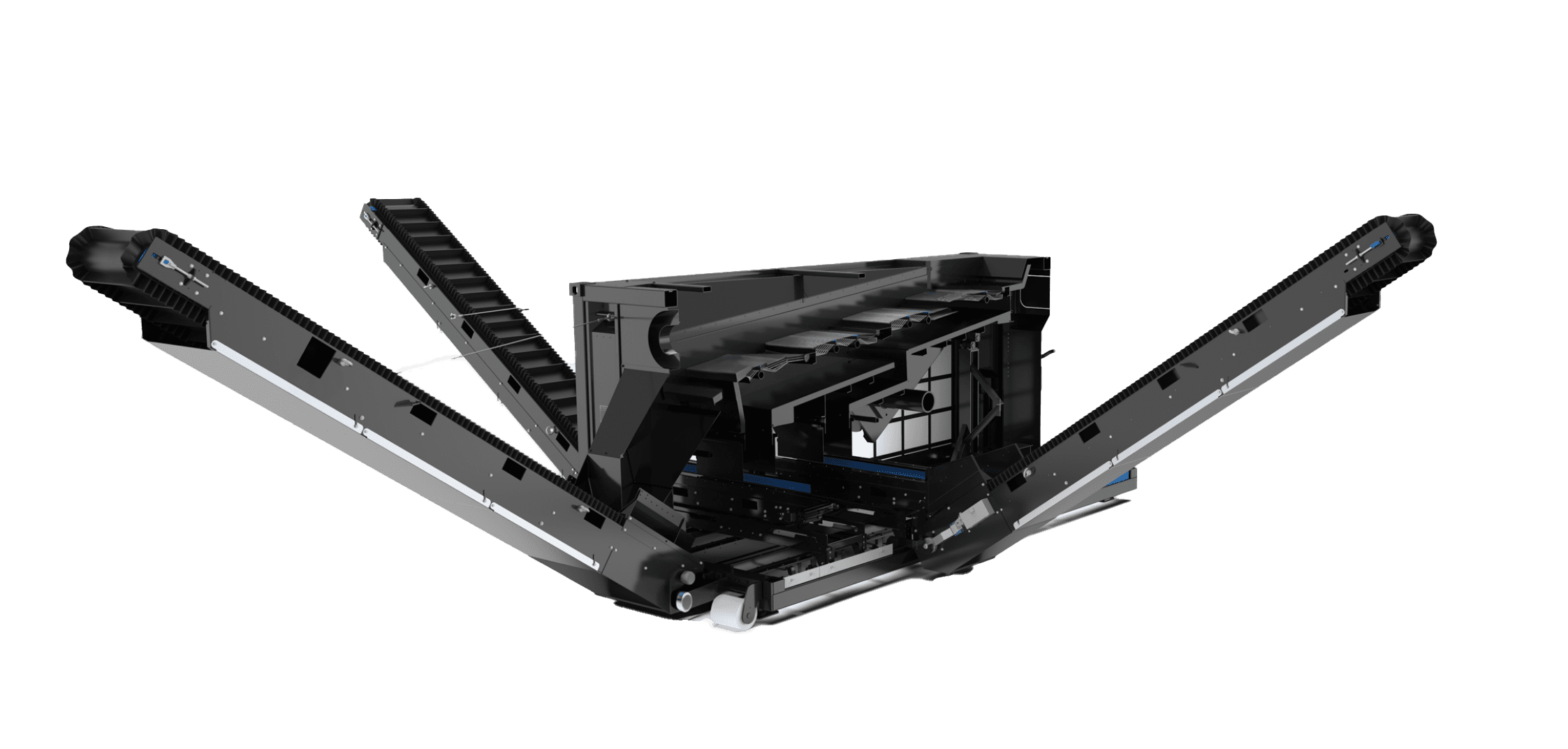

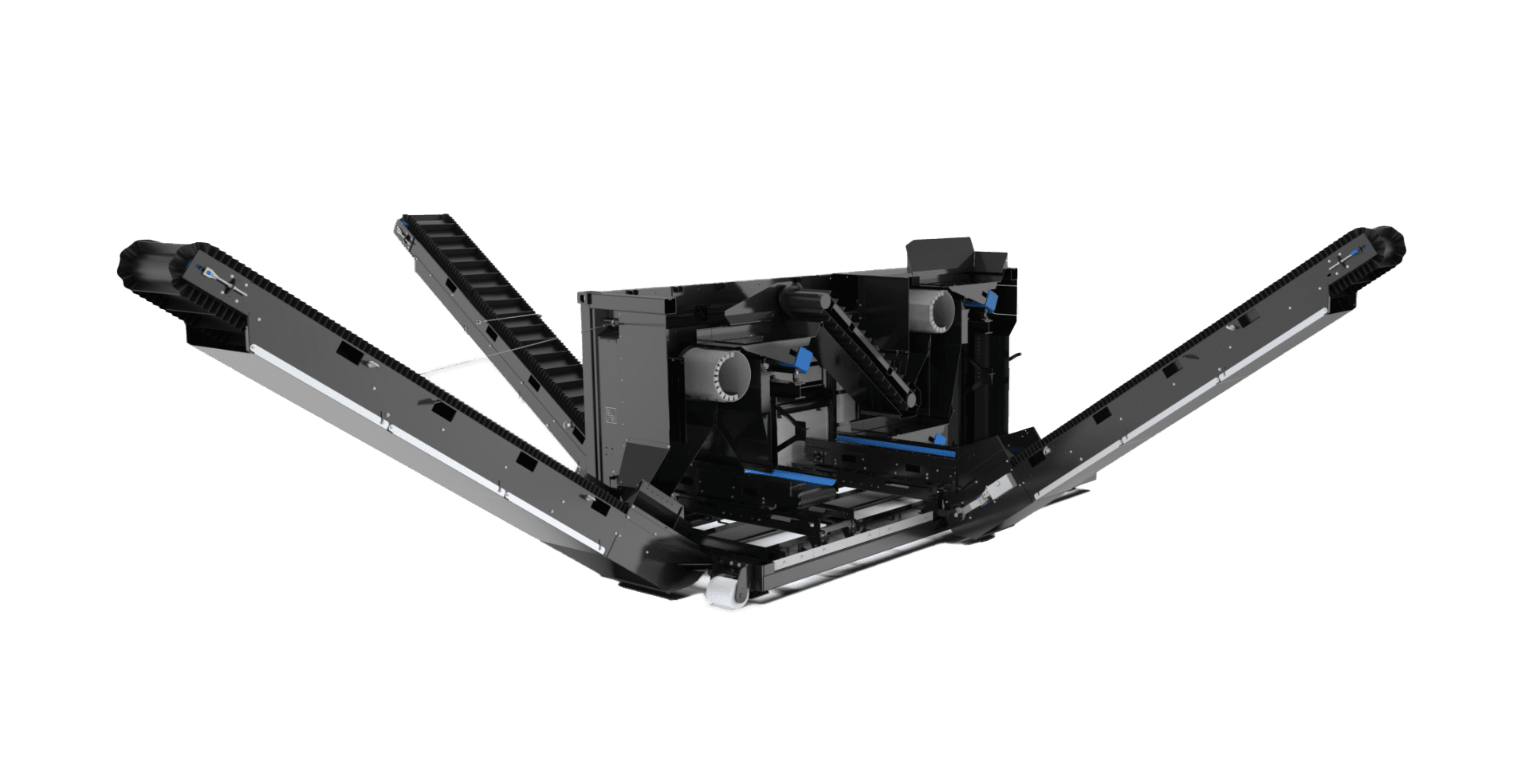

Eddy Current Module

EDDY ACTIVE is an advanced eddy current separator developed by BLUELINE, designed for efficient separation of non-ferrous metals from various waste streams. With its eccentric pole wheel and powerful magnet system, EDDY ACTIVE represents a groundbreaking advance in metal separation technology.

Key features and technical data

-

Rotating magnet system: The eccentric pole wheel enables sorting of particle sizes from 2 to 300 mm with a working height of 1,500 mm and a magnetic strength of up to 500 mT on the belt surface.

-

Automated split edge: Enables reproducible positioning of the splitter at the push of a button, ensuring precise separation.

-

Flexible material discharge: Free choice of discharge side optimizes system layout and an integrated belt scraper prevents material build-up.

-

Quick connect system: Enables tool-free installation of external conveyor belts thanks to foldable arms with snap locks.

How does the technology work?

EDDY ACTIVE uses an eccentric pole wheel that creates a rapidly changing magnetic field. When non-ferrous metals pass through this field, eddy currents are induced in them, resulting in a repulsive force that separates the metals from the rest of the material flow. This enables efficient recovery of valuable metals such as aluminum, copper and brass from waste streams.

Density Module

SORT FINES is an advanced air screen with integrated vibrating feeder developed by BLUELINE, designed for precise density sorting of fine-grained input materials. This technology is considered revolutionary in selective density sorting and impresses with the production of high-purity concentrates.

Key features and technical data

-

Air separation component: Stepless adjustment of the inclination of the sieve insert and the height of the light material barrier. A wide speed range enables optimal adaptation to the input material and two different amplitudes can be selected via control technology. There is a wide selection of different sieve inserts and replacing them is easy thanks to the service position.

-

Dosing chute: Ensures optimal homogenization and dosing using an automated slider position.

-

Powerful fan system: Three high-performance fans enable the operation of three individually adjustable air zones, ensuring maximum separation efficiency.

-

Variable material discharge: Optimized system layout thanks to free choice of discharge side. An integrated belt scraper prevents material build-up.

How does the technology work?

SORT FINES operates by using an air-based separation process where the material is fed over an adjustable screen insert. The three individually adjustable air zones created by high-performance fans allow precise control over airflow, enabling efficient separation of materials based on their density. The integrated vibratory feeder ensures a smooth and controlled feed of the input material, improving separation accuracy and efficiency.

SORT FINES represents a breakthrough technology in density sorting of fine-grained materials.

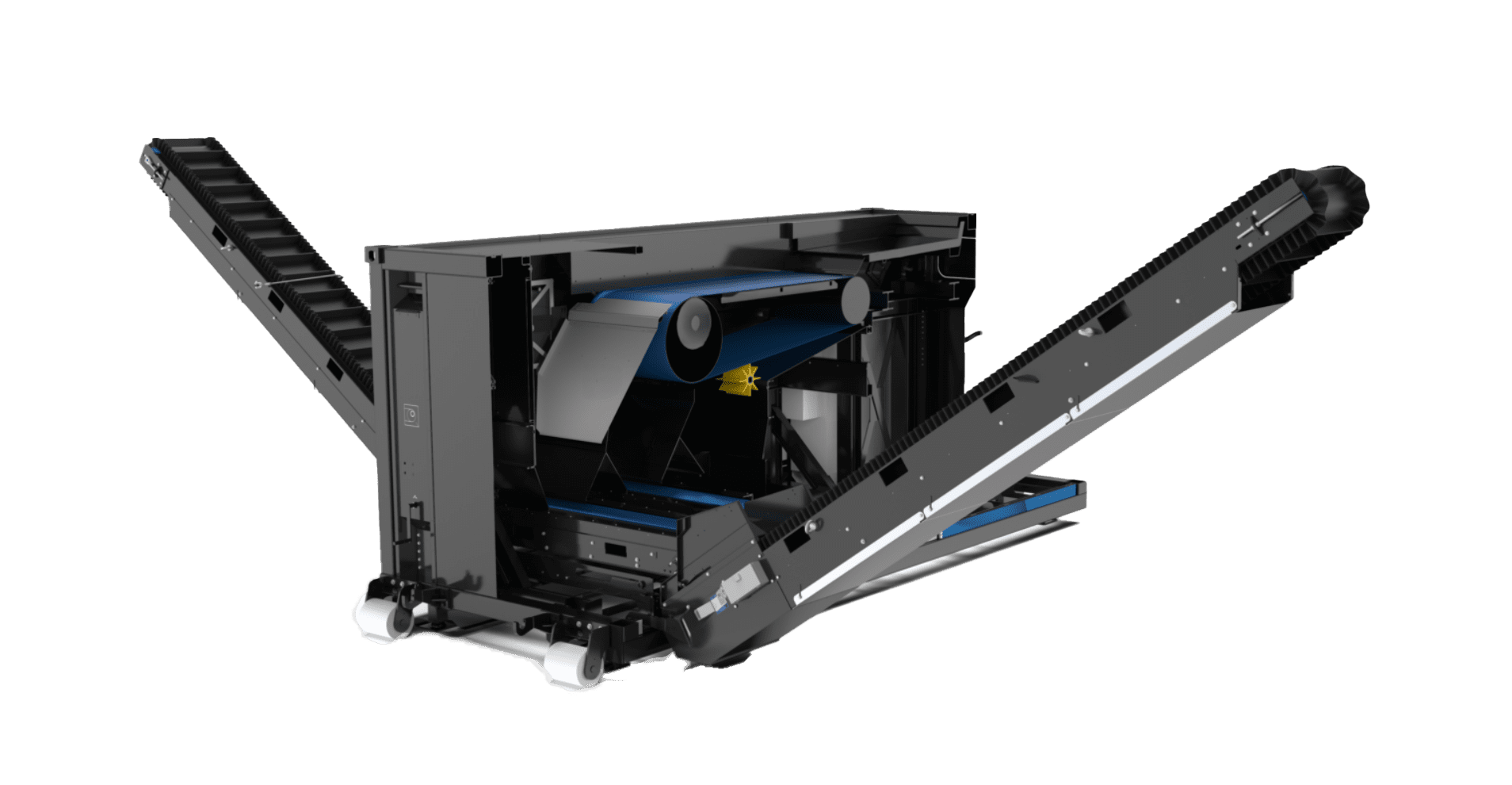

Sensor module

The SENSOR UNCOVER is an advanced sensor-supported sorting device from BLUELINE that uses X-ray transmission technology (XRT) to separate materials based on their density. This sorter can also be equipped with an optional color camera system for additional color and shape recognition.

Key features and technical data

-

X-ray based detection: Uses X-ray transmission to identify particles based on their density, enabling precise sorting of materials with a particle size of 8 to 100 mm.

-

High capacity: Equipped with an acceleration belt that can reach speeds up to 3 m/s and a belt width of 1 meter, ensuring high throughput.

-

Built-in compressed air chamber: The machine has its own compressed air chamber that equalizes air pressure and ensures a stable airflow.

-

Flexible material release: Free choice of discharge side, optimizing system layout. An integrated belt scraper prevents material build-up.

How does the technology work?

SENSOR UNCOVER uses X-ray transmission to measure the density of materials. As the material passes through the X-ray beam, the density is detected and particles with different densities are separated using a nozzle bar and automatic pressure control. The optional color camera system (UNCOVER+) enables additional optical detection based on color and shape, increasing sorting accuracy.

SENSOR UNCOVER represents an advanced solution in sensor-supported sorting technology. Its ability to combine X-ray transmission with optical detection makes it a versatile and effective tool in modern recycling processes.